Search Results

Construction Project Controls Primer

Cost management software is used to integrate cost collection, time charging, expense reporting, work breakdown structure, procurement management, material receipt, accounts receivable, accounts payable, revenue recognition, and standard and custom report generation.

A Numerical Modeling Example – Kraft Recovery Boilers

Good air jet penetration and effective mixing of secondary and tertiary air are desirable for complete combustion and reduced emissions of carbon monoxide (CO) and hydrogen sulfide. Distribution of air to three or more air injection levels produces fuel-rich conditions in the lower furnace that are desirable for smelt reduction and reduced NOx emissions.

View Web PageUpgrades to Existing Wet FGD Systems to Improve Performance, Reduce Operating and Maintenance Costs and Improve Reliability

Upgrading an existing wet FGD system may be an effective way to improve SO2 removal, allow the use of lower cost higher sulfur coals, reduce power consumption, allow for the use of an alternate, lower-cost reagent, and improve the reliability of the system while reducing the operating and maintenance costs.

Absorber Gas-Liquid Contact Devices

Wall rings improve SO2 collection efficiency by reducing the gas bypass in an open spray tower which results from the tendency of the flue gas to hug the walls of the absorber. Wall rings also push out the slurry that runs down from the walls back into the gas stream, improving the contact between the slurry and flue gas.

View Web PageBoiler Cycling Considerations

Cycling operation can shorten the life span of such equipment based on number and duration of cycles. A thorough condition assessment program can determine potential equipment modifications that can make the unit more flexible and alleviate possible problem areas.

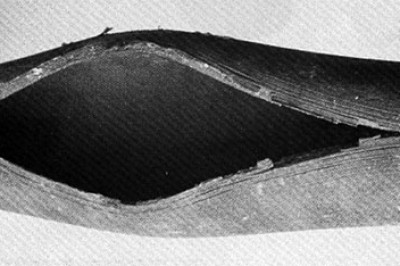

View Web PageFinding the Root Cause of Boiler Tube Failures

Identifying and correcting the root cause of tube failures is essential to help lessen the chance of future problems. A comprehensive assessment is the most effective method of determining the root cause of a failure. A tube failure is usually a symptom of other problems.

View Web PageA Primer on Steam Generation

The steam generator (boiler) evaporates water and supplies high temperature, high pressure steam, under carefully controlled conditions, to a turbine-generator set that produces electricity. The steam may also be reheated in the steam generator, after passing through part of a multi-stage turbine system, by running the exhaust steam back to the boiler convection pass.

View Web PageCO Boilers for the Hydrocarbon Processing Industry

Changes in FCCU catalyst and in process conditions have permitted reductions in the CO content of the gases leaving the unit. These changes also result in the gas temperature to the CO boiler increasing from the 1000F (538C) level to as high as 1450F (788C). New heat recovery boilers on FCC units are designed for these new process conditions.

View Web PageSootblower and Boiler Cleaning Terminology, Principles and Applications

Deposits are removed from the corrugated heating surface by means similar to SCR catalyst cleaning applications such as straight-line sootblower. Swing arm sootblowers and dual media cleaning devices can also be used. Cleaning media must be aimed directly at the gas inlet face of the heating surface with relatively low velocities.

View Web PagePart I - Specifying a Steam Generator

The basic design is derived from the functional requirements of the application. The equipment designer needs to know the key characteristics of all major system inputs and all performance output requirements. This information is essential for setting vital system design parameters such as size, capacity, materials, equipment redundancy level, etc.

View Web Page