Each day is a new day for new possibilities.

What kind of world would we make if we could? A cleaner world with the cleanest energy technologies possible. This story, entitled “Reflections,” dramatizes that idealized world, a world always in our sights at Babcock & Wilcox.

Three power production technologies reflect bright futures for three children. Best of all, this isn’t an imaginary world, but a world we help make possible every day.

A better way

In 1867, Stephen Wilcox said, “there must be a better way” to safely and efficiently generate power. He and George Babcock responded with the design for the first inherently safe water-tube boiler, and the company was born. For over 155 years, Babcock & Wilcox has been researching, inventing and improving better, cleaner ways to do so with a focus on environmental stewardship.

We didn’t just jump on the clean energy train; we're the engine driving it forward.

George Babcock & Stephen Wilcox | 1867

Capturing the science behind carbon capture

The world wants action. More than 100 countries have committed to a carbon net-zero goal by the middle of this century. Nearly half of those 50 years have passed, so we cannot rest.

Every day, our goal is clear: develop and deliver clean power production technologies with the lowest carbon intensity. With over 90 active patents for carbon capture, B&W has been a leader in the research and development of decarbonization technologies for more than four decades.

The Clean Facts:

Proven decarbonization – today

Babcock & Wilcox ClimateBright™ technologies can reduce carbon impact in a multitude of ways: with post-combustion or pre-combustion carbon capture, by utilizing cleaner burning fuels, or by harnessing the energy from a vast array of feedstock to generate hydrogen, steam or syngas with carbon isolation.

Transforming Energy in a Cleaner Way

Providing an extensive range of proven, clean power production technologies

Navigating the energy transition to carbon neutrality can be a challenge. Babcock & Wilcox has been creating energy solutions for years, and it's in our nature to find solutions for lowering emissions from upgrades and parts to new builds. Learn more about the energy transition and how we can help.

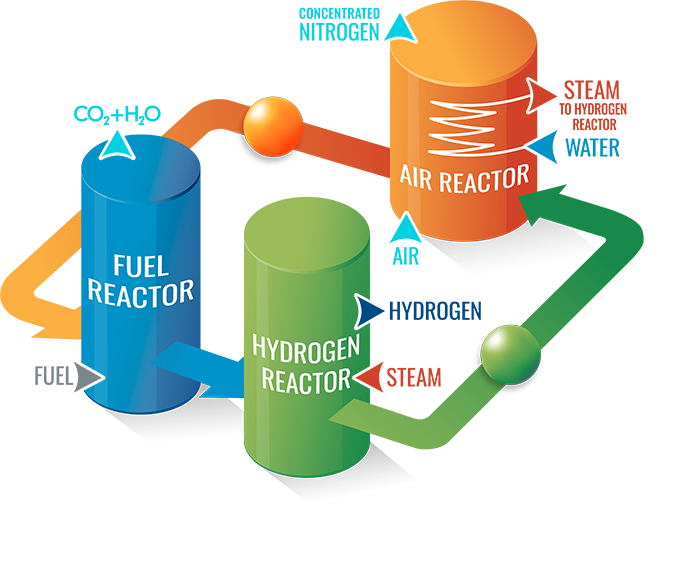

Introducing BrightLoop™ —

The next generation of chemical looping

Babcock & Wilcox, along with our university partner, has demonstrated that Chemical Looping for decarbonization applications is ready for commercial scale-up. Our collaboration has shown that Chemical Looping can effectively separate CO2 while producing hydrogen, steam and/or syngas. Our Chemical Looping system is a game-changing evolution capable of ushering in a new era of decarbonization.

- In-situ carbon capture system

- Breakthrough technology under research with our university partner for 20 years

- Scalable to be adapted economically to large and small installations

- Flexibility for feedstock, including solid fuels (natural gas, biomass, petroleum coke, coal, municipal solid waste for waste-to-energy [WTE] and syngas)

- Successfully demonstrated production of hydrogen from syngas with our university partner at the U.S. National Carbon Capture Center

- An exceptionally versatile oxide in terms of application, cost and abundance

- This platform technology is suitable to support a broad range of applications

A particle breakthrough made it happen

This disrupter, breakthrough BrightLoop technology allowed B&W to make Chemical Looping possible for practical implementation.

The unique particle used in our design was developed by our university partner and is an extremely versatile oxide in terms of application, cost and abundance.

- Its physical characteristics allow it to react to a variety of feedstocks

- It can readily regenerate itself to have extended “shelf life” in operation in a more environmentally friendly and economical way, unlike other Chemical Looping systems that may use copper, nickel, cobalt or others

- Exhibits sustainability by allowing reprocessing or reuse of any fine particles lost from the system

- This makes it applicable to many forms of power generation and industrial processes

- The elements are easy to access and economical

Capturing carbon every day

using a range of leading technologies

POST-COMBUSTION

Our SolveBright™ solvent-based carbon capture technology can be designed to accommodate a customer’s choice of solvents.

- Post-combustion carbon capture with solvent flexibility

- Extensive knowledge to integrate into an existing facility

- Experience with solvent scrubbing solutions since 2005

- Experience across a wide range of industries with various fuels

- Total solution support, from feasibility studies, pre-FEED and pilot unit definition, to full-scale plants, tailored to your needs

OXY-COMBUSTION

Our OxyBright™ oxy-combustion technology has been demonstrated at a large scale and is commercially ready.

- The technology produces a concentrated CO2 stream suitable for sequestration and other uses, such as enhanced oil recovery

- Applicable to a variety of fuel sources

- When biomass or municipal solid waste is used as the fuel source and then combined with carbon sequestration (bioenergy carbon capture and sequestration or BECCS), considered as a net-negative carbon intensity process

- Set the standard as the largest Oxy-Combustion ever demonstrated (Babcock & Wilcox’s 30 MWt plant)

- Selected as the Oxy-Combustion system for the Future Gen 2.0 167 MWe commercial demonstration plant

HYDROGEN COMBUSTION

Our BrightGen™ hydrogen combustion technology is currently in operation in more than 60 water-tube boilers firing hydrogen or hydrogen-blended fuels.

- A combustion technology that produces no CO2 (with 100% hydrogen firing)

- For new installations or as a retrofit in fuel switching applications to fire hydrogen safely and reduce carbon intensity

- Can be co-fired with other gaseous fuels to lessen carbon impact

For a net zero world

It’s an ambitious goal, but we want to do our part.

B&W is a leader, an innovator and an advocate for decarbonization in taking steps toward reducing greenhouse gases.

- Leader — Proven pre- and post-combustion carbon capture technologies for more than four decades

- Innovator —A history of research and innovation, with more than 17,000 technology patents, including a Chemical Looping decarbonization technology ready for commercial demonstration

- Advocate — It's only natural that Babcock & Wilcox commits resources for the pursuit of decarbonization technologies to make cleaner energy production standard. B&W is a resource for knowledge and insight about this subject

We collaborate with universities to create best-in-class solutions; we partner with industry leaders and energy producers to develop programs that push the limits; and we have technologies that help improve energy production in over 90 countries.

From electric power generation to emissions, waste treatment and environmental engineering — for industries ranging from steel, cement, oil and gas to carbon black, food manufacturing, pulp and paper — we are ready for a clear path to a cleaner future.

For more information, download the brochure.

Babcock & Wilcox.

We’re here to: CO2llaborate, CO2operate, CO2mmunicate and CO2nserve.