OxyBright™ Oxy-Fuel Combustion

B&W has always been at the forefront of advancing steam generation technologies. One of these key advancements was the development of oxygen-combustion technology, known commercially as B&W’s OxyBright™ technology. B&W’s research into oxy-combustion began over 40 years ago in an enhanced oil recovery application, advanced from both small and large-scale pilot plants into full-scale commercial design, and progressed to a low-risk, commercially ready solution.

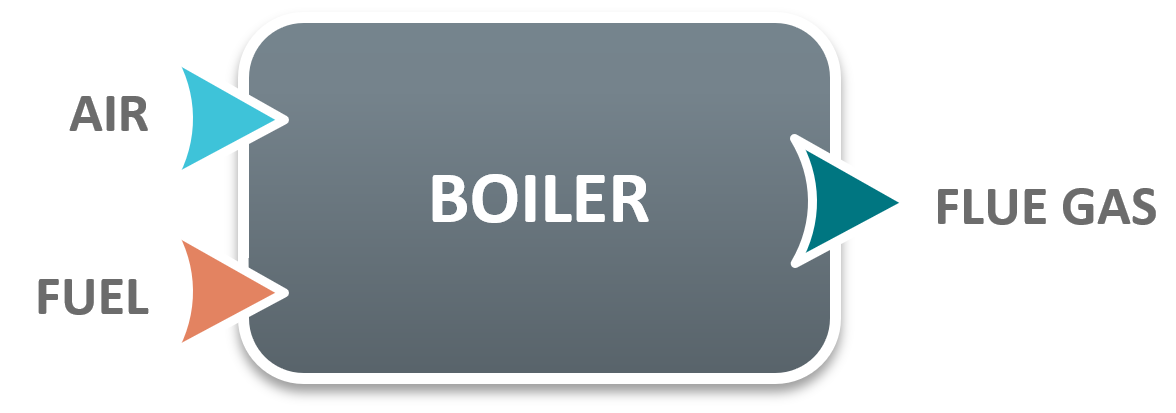

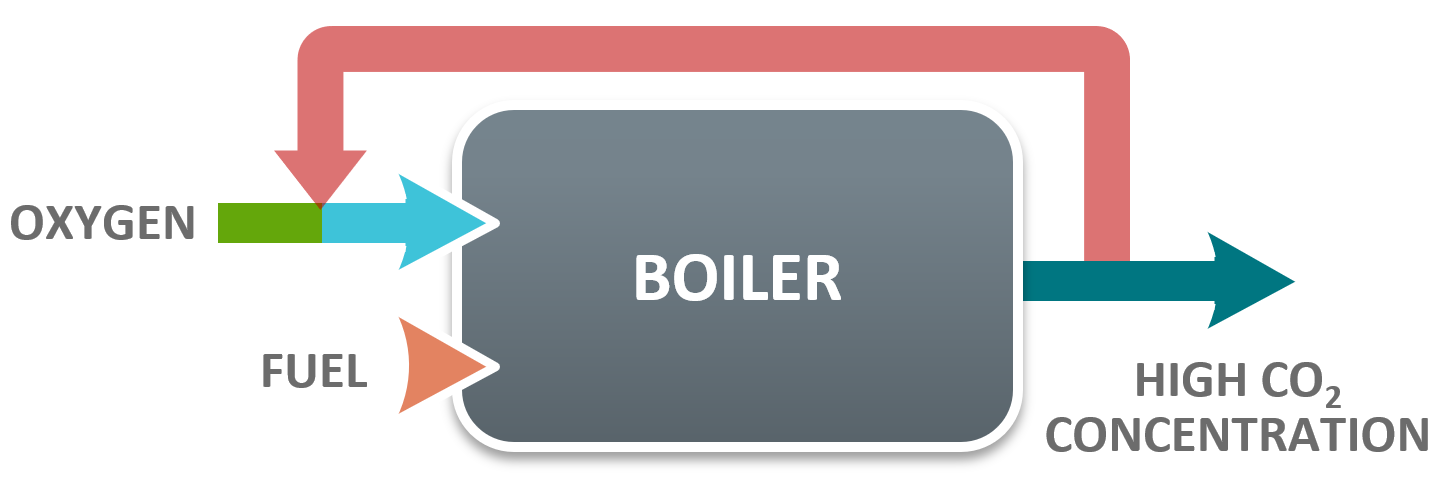

Oxy-combustion is the combustion of fuels with nearly pure oxygen and recycled flue gas (instead of air). The resultant flue gas byproduct is primarily carbon dioxide (CO2) which facilitates the capture of high-purity CO2 without the need for a post-combustion scrubber.

Process

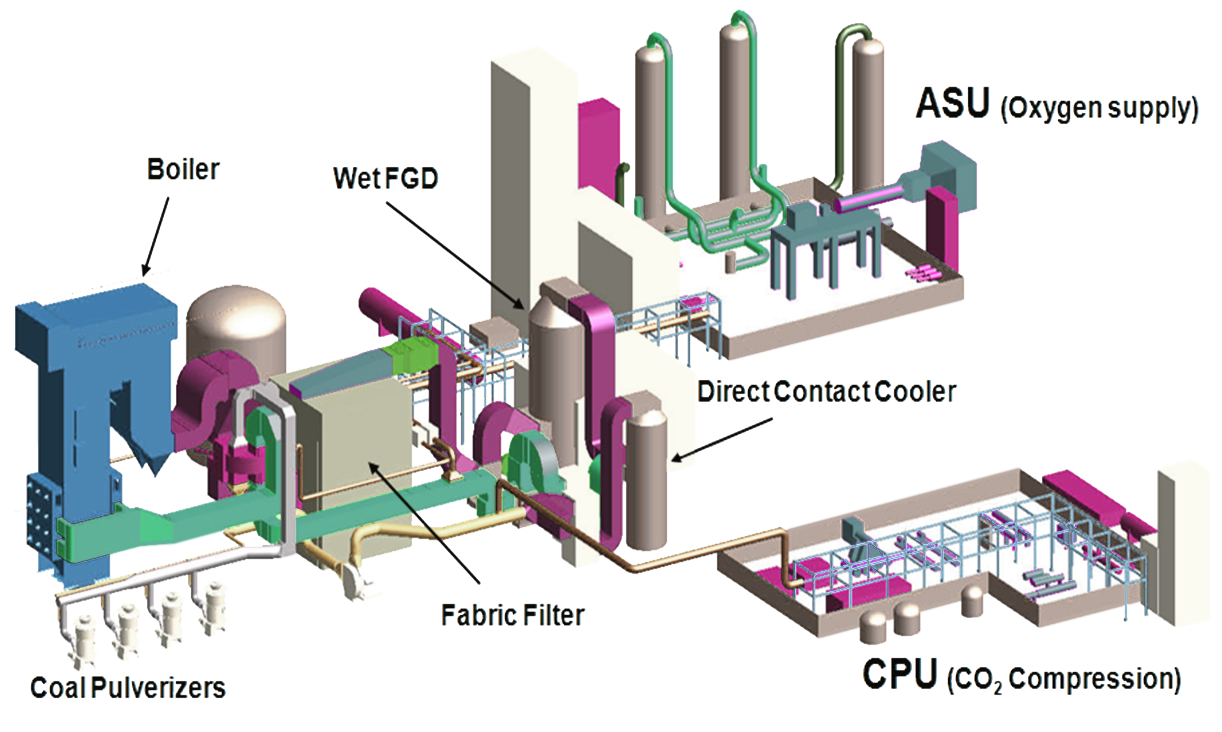

In B&W’s OxyBright process, boiler combustion air is replaced with nearly pure oxygen. Nitrogen that would normally be conveyed with the air through conventional air-fuel firing is excluded. Instead, a portion of the CO2-rich flue gas is recirculated to a conventional pulverizer/burner/fluidized bed system, substituting CO2 for the nitrogen in the furnace. Oxy-combustion creates a flue gas that is primarily CO2, rather than nitrogen, and includes typical products of combustion. The non-recirculated flue gas leaving the boiler is cleaned using conventional particulate and sulfur removal systems and sent to the compression purification unit (CPU), where a high-purity CO2 stream is produced suitable for capture and transportation or other uses.

B&W’s OxyBright system design creates a CO2-rich ‘synthetic’ air and can be operated in either air-firing or oxygen-firing mode. Transitioning between the two modes requires no downstream modifications to the system, providing the ultimate flexibility in plant operations.

The road to commercialization

In 2015, B&W was selected as a primary technology provider to participate in the U.S. Department of Energy (DOE)-funded FutureGen 2.0 Oxy-Combustion project. The project was to demonstrate oxy-combustion technology on an existing 168 MW pulverized coal-fired unit. Although not ultimately proceeding to construction, the project significantly advanced the development of the technology to support future full-scale oxy-combustion projects. Significant engineering milestones were completed, including contract-level design on the oxy-combustion boiler, the air separation unit (ASU), the CO2 compression and purification unit (CPU), and the turbine islands.

In addition to the engineer-procure-construct (EPC) project schedule and project performance guarantees, detailed lessons-learned and project risk analyses were developed as part of the commercial offering, all of which will be implemented into future projects. Through B&W’s continued advancement and development work with outside partners, our OxyBright oxy-combustion technology is commercially ready and available to support global decarbonization projects.

Flexible applications

OxyBright oxy-combustion can be retrofit onto existing boilers or can be engineered and supplied with new boiler installations. The flexibility of the technology allows application with both gaseous and solid fuels as shown in the process flow diagrams below.

Traditional Air Combustion

Oxy Combustion

CO2 concentration increases from 10-14% to 80-85% with oxy combustion.