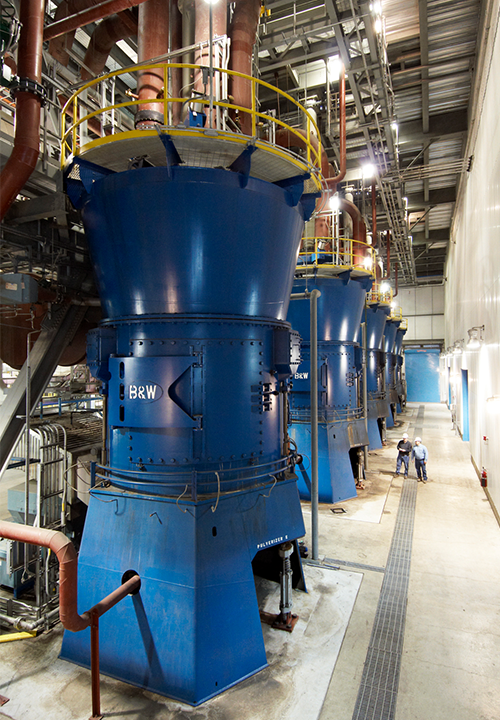

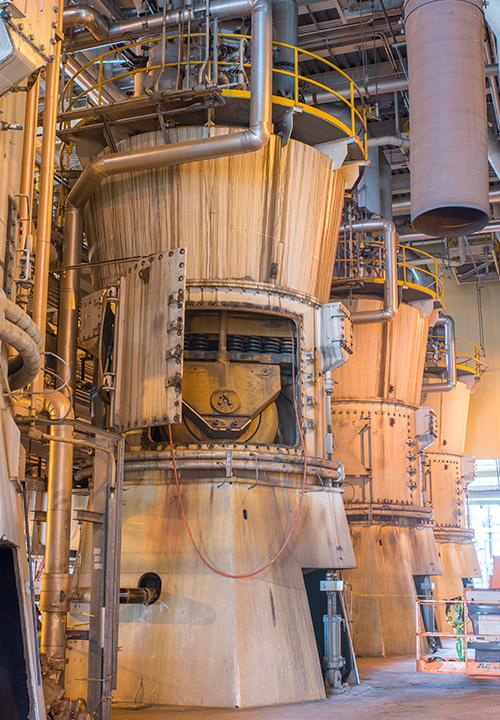

Pulverizers / Mills

Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW.

B&W's pulverizers, found at power stations throughout the world.

From our original E/EL ball-and-race type pulverizers for lower capacity applications, to the latest B&W Roll Wheel™ pulverizer capable of grinding up to 230,000 pounds of coal per hour (104,300 kg/hr), we set the standard for high availability, reliability and low maintenance.

Every B&W pulverizer is built with a commitment to quality, durability and operational excellence:

- Operates a minimum of 3,000 hours between internal inspections

- Maintains fineness and capacity throughout the wear life of the grinding elements

- Accepts and grinds a wide variety of coal types

- Requires a minimum number of replacement parts

- Allows for easy maintenance through a single, large access door

- Includes capabilities to manually or automatically change spring loading and/or coal fineness

- Utilizes the most advanced wear and erosion protection Today, with more than 1,100 B&W Roll Wheel pulverizers sold worldwide and six different sizes burning a variety of coals, B&W has the proven design and operating experience to meet your specific project requirements. This performance has made the B&W Roll Wheel pulverizer the pulverizer of choice for coal-fired boiler operators and owners.

World-Class Wear Materials

In 2015, B&W and Magotteaux formed a strategic alliance to provide world-class wear material products and services to customers around the globe. Through the alliance, we can offer:

- Metallurgical expertise and patented technologies for specialty alloys and composite materials, so your equipment has greater performance and longer life

- Proven and customized technology and parts for mills of varied OEMs, fuels, wear materials (low chrome, high chrome, ceramic)

- Xwin® technology that extends running life of tires and segments, increases time between maintenance cycles, reduces O&M costs, lengthens consistency of grinding profiles and reduces power consumption

- Worldwide safety- and quality-certified manufacturing facilities, replacement parts stocking programs, and a network of field service engineers for reliable, responsive service

Aftermarket Products & Services

In addition, we continually develop new technologies, upgrades, replacement parts, and inventory management programs to improve reliability and performance, and to reduce operating and maintenance costs of our B&W Roll Wheel and E/EL pulverizers, as well as CE-type mills.