Cooling Tower Parts and Components for Wet and Dry Systems

Improving Cooling System Performance, Efficiency & Reliability

Since 1936, B&W Environmental has engineered, installed, upgraded and serviced an extensive range of turnkey cooling systems.

In addition to providing cooling tower pars, our wide range of capabilities include basic technical assistance and field service support as well as installation, commissioning and start up, performance testing and optimization, including recommendations for upgrades, energy savings and wet-dry conversions.

A dedicated, multi-disciplined after-sales team is committed to executing projects successfully and in compliance with various international engineering standards. We have successfully completed many equipment upgrade projects while the plant is operating, reducing or eliminating downtime.

- Wet, dry and hybrid cooling system solutions

- Wet-to-dry system conversions

- Maintenance, overhaul and upgrades

- Cooling tower parts, components and field service

- Cooling system inspections

- Online monitoring

- R&D testing

- Operational and maintenance training

SPIG Wet Cooling Tower Parts

As a leading worldwide supplier of SPIG® cooling system solutions, we provide comprehensive after-sales services including operational support, maintenance, training, upgrades and replacement parts.

Our cooling tower parts and replacement components are reliable and proven to keep your equipment operating at optimum efficiency levels, regardless of original manufacturer. Quality components are available for quick delivery from a worldwide network of service locations to provide you with continuous and safe plant operation.

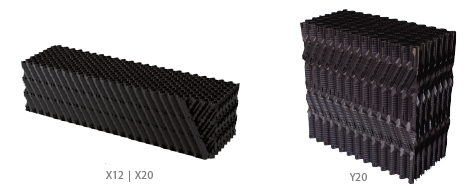

Film Fills

SPIG wet cooling system film fill turns water droplets produced by distribution nozzles into a thin film for highly efficient cooling by producing a large area for effective heat transfer and evaporation.

We use high-quality materials to help extend the lifetime of the cooling tower and reduce the frequency of component replacement.

In applications with particularly dirty process water, our SPIG LC fill type was developed to achieve the best compromise between high-thermal performance and water containing higher amounts of contaminants.

Notes:

- Standard temperature range is –20C to 55C for PVC and –20C to 70C for PP.

- Minimum temperatures as low as –40C can be achieved with special additives in the raw material.

- Maximum temperatures as high as 70C for PVC or 80C for PP can be achieved with special additives in the raw material.

- PP can be provided with fire-retardant properties as per ASTM E84 FI<25 or in accordance with CTI 136 Code.

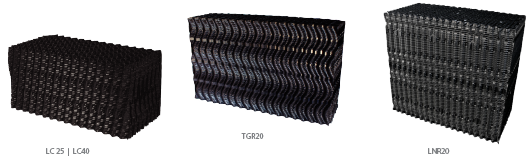

Film Fill Protection Device

Our film fill protection device is designed to protect against damage to spray nozzles and the film fill upper layer in applications where water contains high levels of contaminants such as sand or debris. This device is composed of PVC-extruded pipes and PP spacers to be assembled onsite, and positioned on the upper surface of film fill. It is available in varying lengths to fit into any cooling tower dimension.

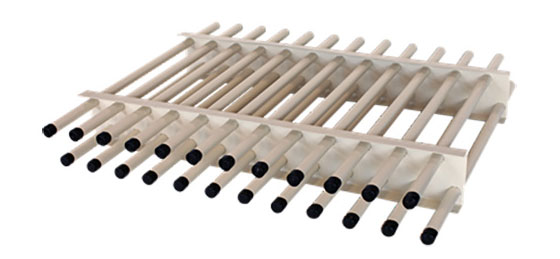

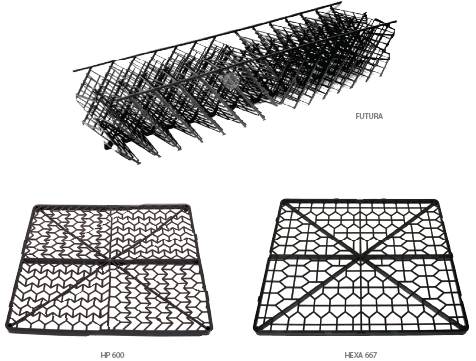

Splash Fill

We provide a wide range of SPIG splash fill components to facilitate heat transfer capability by maximizing water/air contact. Our wide range of splash fill components were developed based on extensive field experience, particularly with water which is prone to clogging, such as sea and geothermal water.

Notes:

- Standard temperature range is –20C to 55C for PVC and –20C to 70C for PP.

- Minimum temperatures as low as –40C can be achieved with special additives in the raw material.

- Maximum temperatures as high as 70C for PVC or 80C for PP can be achieved with special additives in the raw material.

- PP can be provided with fire-retardant properties as per ASTM E84 FI<25 or in accordance with CTI 136 Code.

Distribution Nozzles

Effectively designed distribution nozzles help ensure a uniform delivery of water over the fill. SPIG ECOJET and NEW STATIC distribution nozzles have been developed after extensive and successful performance test results and are proven in many installations.

Our ECOJET and NEW STATIC distribution nozzles provide versatility, high reliability and outstanding performance, and can be manufactured with V2 as per UL-94 standards for self-extinguishing properties.

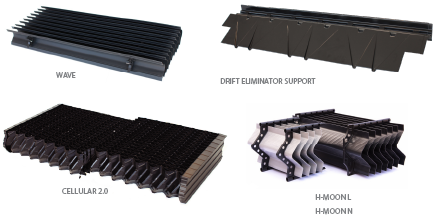

Drift Eliminators

Installed above the distribution level, drift eliminators play an important role by capturing water droplets entrapped in the air stream that otherwise would be lost to the atmosphere. Current SPIG drift eliminator designs have been developed and refined through the years based on field applications and performance testing.

Notes:

- Minimum temperatures as low as −40C can be achieved by means of special additives into the raw material.

- For PP, maximum operating temperature is 80C.

- The efficiency of drift eliminators is based on the constant air velocity and assumes that drift panels are installed in accordance with the manufacturer’s specifications.

- Elements available in PP can be supplied with self-extinguishing properties by request.

Noise Attenuation System

Typical noise abatement devices are available as baffles at the air inlet and/or on top of fan stacks, mechanical equipment coffins, and low-noise cladding made from FRP. In addition, our Impact Attenuation Wave (IA-Wave) noise attenuation system can be installed to reduce high-frequency noise produced by water fall from fills to water in the basin. This system consists of special inclined profiles adequately spaced to allow for quick drainage of the falling water. The system is composed of high-quality PVC-extruded elements packed by PP spacers and is installed over the water level in the basin, typically on FRP beams.

Air Inlet Louvers

Air inlet louvers are available to reduce the potential for debris to enter the basin at the cooling tower air inlet. The device is also helpful to avoid the risk of algae and bacteria propagation caused by direct sunlight shining on the basin water. Constructed with PVC light gray thermoformed panels in a standard width of 65 mm, we can also customize panel dimensions to fit most cooling tower applications and FRP support elements.

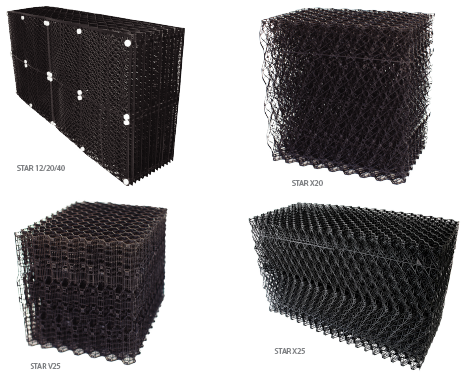

Multi-Row Bundles

For hybrid cooling towers, we can provide heat exchangers with a multi-row bundle configuration. Our controlled aluminum finning process is adaptable for G or L fin configurations with different FPI and pipe diameters from 1 in. to over 2 in. This provides the flexibility for a wide range of applications.

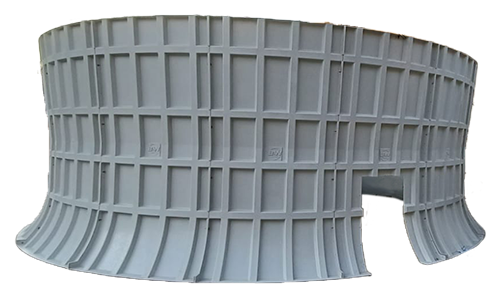

Fan Stacks

A wide range of fan stack diameters and heights can be supplied through reliable partners utilizing SPIG proprietary molds. Flanged fan stack connections are typical, but an overlapped design can also be supplied when requested. Typical material is standard polyester resin or fire-retardant FRP with FSI<25 as per ASTM codes.

Other Accessories

We have developed many other exclusive components to facilitate installation or reduce transportation costs, such as spacers for FRP structures and sleeves, FRP main column supports, and basin shims. We can also supply:

- All mechanical components for electric motors, gear boxes, driving shafts and fans

- Backstop devices, lubrication systems, and sensors to monitor mechanical components

- Firewalls to prevent fire propagation between cells

- Ladders, platforms and stair cases

- UNICO cooling tower remote monitoring system

- FRP risers to feed water in each cell, valves

- Vacuum systems, dampers and mixing devices for dry section of hybrid cooling towers

- Fire-fighting system

- Cleaning system for heat exchangers