SolveBright™ Post-Combustion Carbon Capture

B&W’s history with carbon capture began in 1979 when we evaluated oxy-coal combustion for enhanced oil recovery. We began initial research of post-combustion carbon capture processes in 2005. This led to the development of the SolveBright™ regenerable solvent absorption technology scrubbing process which used an advanced amine-based solvent with demonstrated superior performance to that of competing solvents at the National Carbon Capture Center.

Since that time, our design has evolved to allow solvent flexibility to provide solutions which are adapted to customers’ unique applications.

Process

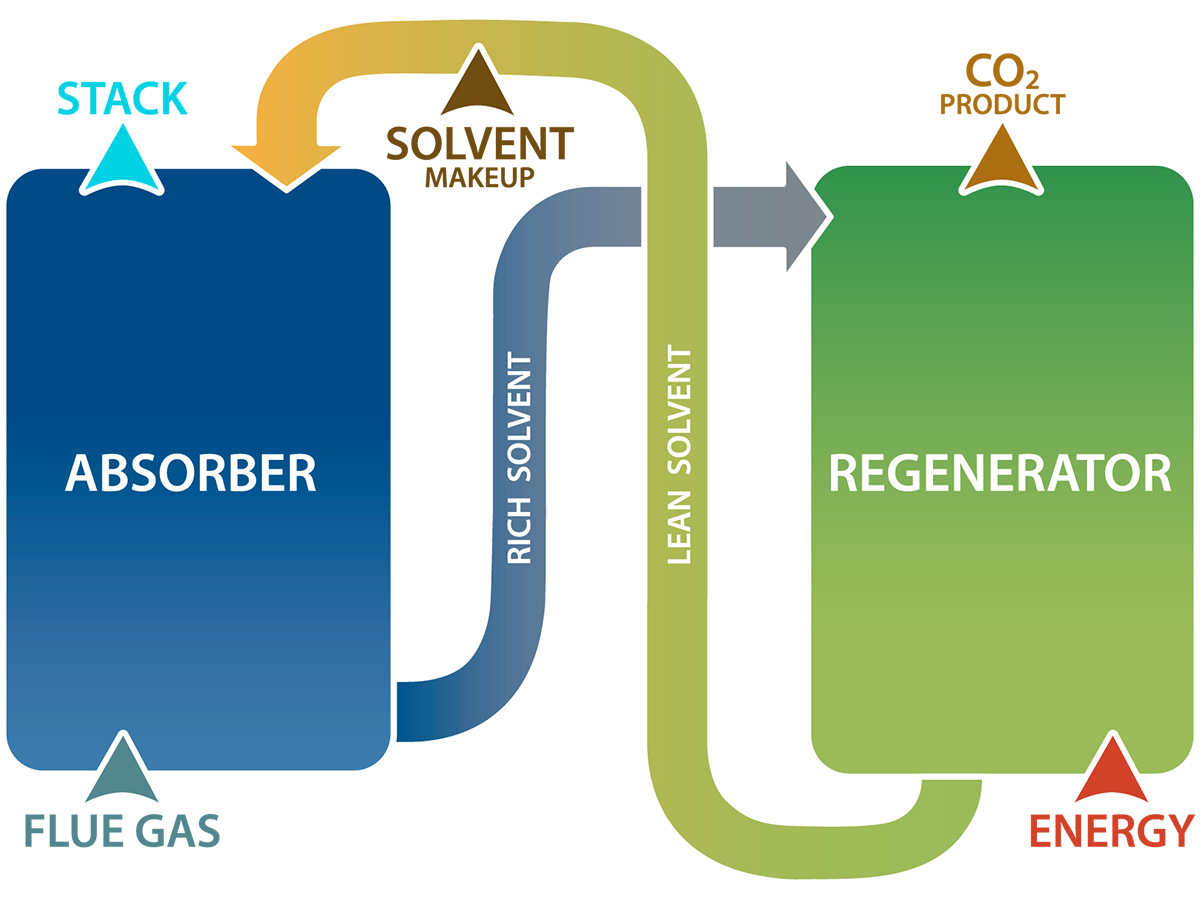

B&W’s SolveBright carbon dioxide (CO2) scrubbing systems are post-combustion carbon capture technologies which work by absorbing CO2 directly from flue gas in an absorber using a regenerable solvent. The CO2-laden solvent is sent to a regenerator where it is heated, and the CO2 is released as a concentrated stream for compression and transport to a CO2 sequestration hub or liquified and used for beneficial purposes. The solvent is then recycled to the absorber for additional CO2 capture.

B&W Advantages

With more than 50 years of experience with flue gas treatment systems and integrated emissions control, we understand the challenges of integrating post-combustion carbon capture technologies into a plant. Let us use our experience to earn your trust as you move to decarbonize your operations.

- Solvent flexibility, allowing us to customize an optimal CAPEX and OPEX solution for each application

- Extensive knowledge of combustion processes and thermal management associated with combined heat and power systems which allows us to intelligently integrate the carbon capture system into an existing facility

- Knowledge of solvent scrubbing solutions for carbon capture since 2005; we understand the process, the equipment and the innovation behind the various type of solvents used

- Experience across a wide range of industries with various fuels: from utilizing waste and biomass as fuels to industries such as cement, steel, chemical, oil and gas, pulp and paper, food and beverage, and many others looking for reliable decarbonization partners

- Total solution support, from feasibility studies, pre-FEED and pilot unit definition, to full-scale plants, tailored to your needs

- Global presence to support a wide range of customers regardless of location

B&W Technology

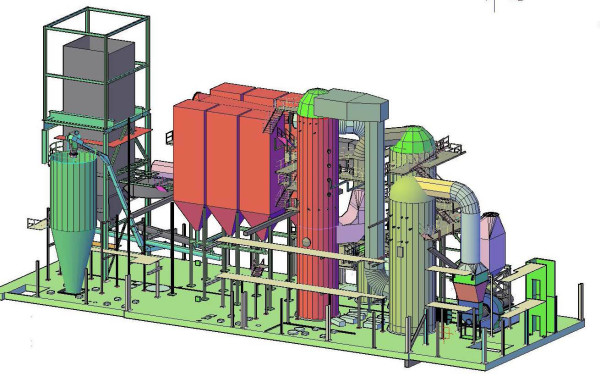

Anticipating the need to reduce greenhouse gas emissions, B&W’s efforts in post-combustion carbon capture started in 2005 with extensive laboratory testing. Having completed pilot-scale testing we designed a full-scale commercial carbon capture plant suitable to capture 1500 metric tons of CO2 per day from a flue gas source.

The plant design consists of a full package of engineering documentation, including piping and instrumentation drawings, a three-dimensional plant layout, equipment lists, schematics, preliminary mechanical design and fabrication drawings for major process vessels, foundation and structural steel designs, procurement packages including equipment specifications for all major equipment, construction estimates, engineering man-hour estimates, process flow diagrams, and a complete material and energy balance for the plant.

B&W can support your small or large-scale post-combustion carbon capture projects, from initial plant surveys and technology evaluation to plant commissioning and start-up.

B&W Support and Commitment

As an open technology integrator for various solvents, B&W can provide support during your complete path of CO2 capture and decarbonization, from project concept and assessment through design, delivery, construction and startup. Our approach to providing solutions is based on our extensive experience and strong technology knowledge in overall plant integration, including:

- Pilot or small-scale units to support Front-End Engineering Design (FEED) studies

- Review and evaluation of alternative project approaches

- Project scheduling to meet key milestones

- Complete documentation packaging

- Design, supply and integration of flue gas pre-treatment systems to optimize operating conditions of the entire carbon capture plant

Flue Gas Pre-Treatment for Post-Combustion Carbon Capture

Solvent-based scrubbing technologies often require reductions in various constituents found in the incoming flue gas. Flue gas pre-treatment is important for the scrubbing process to result in optimum effectiveness of the carbon capture technology. Additionally, project economics are improved by ensuring optimum flue gas conditions entering the system, including reduced moisture and pollutants, and favorable temperature range.

B&W’s proven and industry leading emissions control solutions can be integrated into your carbon capture system for optimized flue gas conditions.