Search Results

Assessing Structural Integrity and Remaining Life of Boiler Tubing

Power plant operators looking to get the most out of their existing steam generating systems are constantly faced with the decision to “run, repair or replace” their equipment and prevent unplanned outages that impact operations. As boiler tube failure is the leading cause of unscheduled availability loss, an important preventive measure is testing boiler tubes to analyze their condition and gauge their remaining useful life.

View Web PageBoiler Fitness Survey for Condition Assessment of Industrial Boilers

B&W provides an overview and benefits of establishing a formal boiler fitness survey program, focusing on units in industrial applications.

View Web PageChoosing Between Crossflow and Counterflow Cooling Towers

Crossflow and Counterflow cooling towers are two different types of wet cooling systems used to remove heat from industrial processes. Review the primary differences between the two.

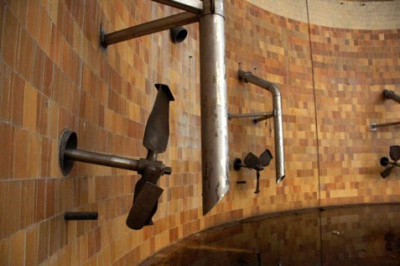

View Web PageBenefits of Cylindrical Superheater Casings for Waste Heat Recovery Systems in Sulfuric Acid Plant Applications

B&W Chanute developed its Optimus cylindrical superheater casing for waste heat recovery superheaters and economizers for hot, high-temperature applications.

View Web PageReducing Potential Superheater Casing Failures in Sulfuric Acid Plant Applications

In the superheater inlet transition ducts, environmental exposure can lead to cracks and/or warping of the casing and stiffeners. What modifications can help reduce failures?

View Web PageWhy Choose Hybrid Cooling Towers?

Hybrid cooling towers leverage both wet and dry cooling technologies to reduce plume volumes and the consumption of water, minimizing the impact on the environment. This cooling system technology is an optimal solution for certain conditions. What are they, and how does the technology work?

View Web Page10 Ways to Minimize Grate Wear in a Waste-to-Energy Boiler

Thermal and mechanical grate wear increases maintenance costs. If the grate is not operated correctly, or if combustion is not properly managed, wear accelerates and there is risk of substantial damage. As a fuel, waste tends to be unpredictable and varies over time. It presents challenges for the plant, and can cause mechanical, thermal and chemical wear.

View Web PageReagent Preparation and Dewatering in a Wet FGD System

If limestone consumption must be increased to improve SO2 removal, the reagent preparation and dewatering systems may be undersized. In most cases, higher SO2 removal requires a finer grind than what older systems were originally designed to achieve.

View Web PageBid Evaluation Example

The example below provides a comparison between two industrial boiler bids where one bidder has a higher price but with a unit that has higher efficiency. Bid 1 guarantees 86.5% efficiency with a price of $10,400,000. Bid 2 guarantees 87.5% efficiency with a price of $11,200,000.

View Web PageLimestone Forced Oxidation System Upgrades

A wet FGD can be converted to forced oxidation using the existing reaction tank, or in some cases, an external oxidation tank can be used. This conversion will minimize scaling from utilization of stable system chemistry and creating a saleable byproduct which will decrease disposal costs.

View Web Page