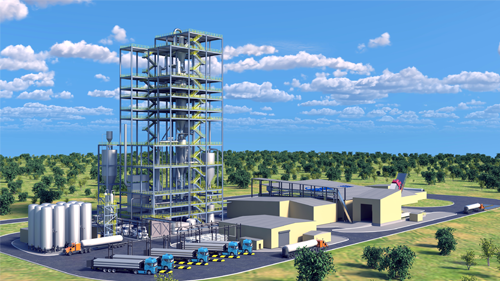

BrightLoop™ Low-Carbon Hydrogen Technology

Using chemical looping technology for the production of low-carbon hydrogen, steam or syngas

As the world advocates for decarbonization, B&W is responding by looking for innovative ways to contribute to the energy transition and a cleaner tomorrow. Our BrightLoop™ technology can be used for a wide range of applications. The process produces desirable outputs such as hydrogen, while isolating carbon dioxide (CO2) for capture and storage/sequestration or beneficial use.

This low-carbon hydrogen technology is a catalyst for helping the industrial world transition to a more sustainable future, supporting the international goal of net-zero CO2 emissions by the middle of the century. Our chemical looping technology can be used in many different processes to arrive at several outcomes; hydrogen generation is just one.

BrightLoop Chemical Looping Advantages

The primary benefits of B&W’s BrightLoop chemical looping technology include:

Hydrogen From Multiple Feedstocks

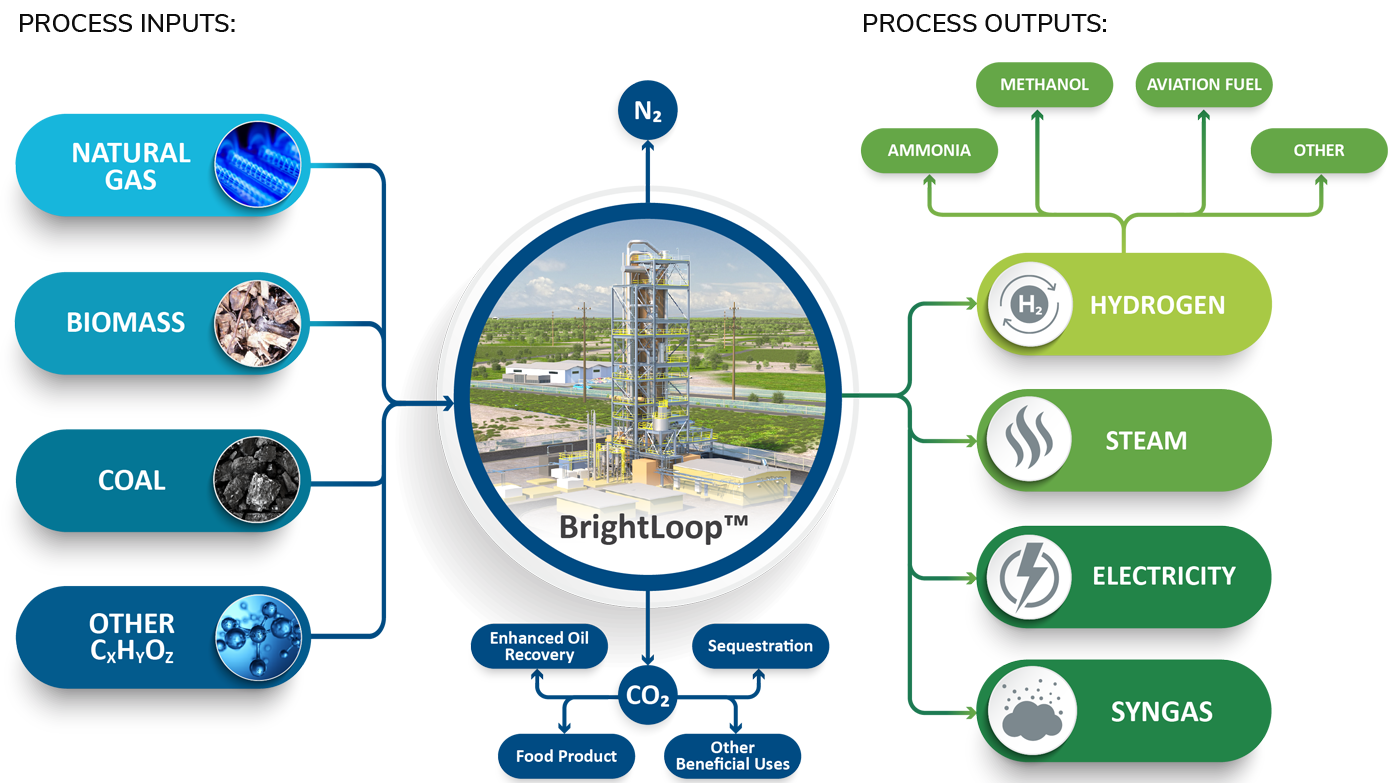

B&W’s BrightLoop chemical looping technology utilizes a variety of solid and gaseous fuels as feedstock to produce a stream of nearly pure hydrogen separate from a stream of CO2. This greatly reduces the amount of energy and fossil fuel required to produce hydrogen from hydrocarbons while also effectively and inexpensively isolating carbon dioxide.

Scalable for a Range of Applications

The BrightLoop process is scalable to accommodate small, medium and large applications. These various sizes accommodate market needs such as supporting local generation for transportation, centralized hydrogen hub generation, and industrial uses.

Competitive Hydrogen Cost

BrightLoop chemical looping will produce low-carbon hydrogen at a cost better than current large-scale hydrogen generation technologies such as steam methane reforming (SMR) with carbon capture or electrolysis.

High Rate of Carbon Captured

Inherent CO2 isolation without the need for expensive carbon separation equipment is part of the process. Generally, BrightLoop also has much lower Carbon Intensity (CI) scores as compared to other hydrogen production methods when combined with carbon capture due to the inherent separation of CO2 and the wide range of feedstocks available. It has the potential to allow the continued use of solid and gaseous hydrocarbons in a cleaner, more environmentally friendly way, while still contributing to net-zero goals.

Process

The BrightLoop technology is a novel chemical looping process that is based on the oxidation and reduction of an oxygen carrier particle. The feedstock reacts with oxygen-carrier particles in a fuel reactor, forming reaction products which are predominantly CO2, while reducing the oxygen-carrier particles.

The reduced oxygen-carrier particles then move to a hydrogen reactor where they react with steam to partially oxidize the particles and generate a stream of hydrogen. This reaction means that the hydrogen is produced from the steam – it is not separated from the other constituents of the feedstock.

The oxygen-carrier particles are then transported to an air reactor where they are regenerated with air back to their original state. The products of these reactors are predominantly concentrated nitrogen with minimal oxygen. The fully regenerated particles are then returned to the fuel reactor to continue the “loop” process. The fuel and hydrogen reactors use moving-bed technology while the air reactor uses fluidized-bed technology.

Gaseous products generated in each reactor are cooled using various heat exchangers including steam generators that produce the steam needed to create hydrogen and cleaned of undesirable emissions using typical environmental control technologies.

The process can also be configured to produce steam for process or electricity generation, or syngas for liquid fuel or methanol production, all with CO2 isolation.

Applications with Various Product Outputs in a Low-Carbon Environment

The flexibility and scalability of B&W's BrightLoop technology, both in terms of usable feedstock and product outputs, provides for a wide range of industry applications. While hydrogen production is certainly considered a key component of the energy transition, other configurations and functions of BrightLoop chemical looping are available to meet low-carbon initiatives. Examples include:

- Low-carbon hydrogen production as an alternative to steam methane reforming

- Net-negative energy production utilizing biomass

- Clean coal power production

- Waste byproduct utilization

Ready for Commercial Deployment

Under a DOE-sponsored project, B&W built a 250 kWt coal-based CDCL pilot facility to demonstrate the fuel reactor and air reactor operation for application to steam (and subsequently, power) generation. On another project, continuous low-carbon hydrogen generation was demonstrated at the 250 kWt pilot unit constructed and tested at the National Carbon Capture Center in Alabama.

Given the success of the pilot units, we are ready to commercially demonstrate the technology at a larger scale. B&W is working on projects to demonstrate low-carbon hydrogen and steam production while utilizing the most applicable fuel feedstock.