Selective catalytic & non-catalytic reduction (SCR & SNCR) for high performance NOx control

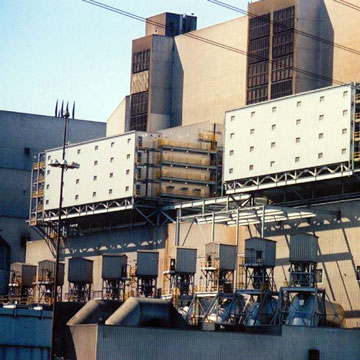

Selective catalytic reduction (SCR) systems are the technology of choice as the most effective method of post-combustion NOx reduction. As a leader in providing complete project packages including system design and construction, ammonia storage and delivery systems, reactor and catalyst design, control systems, and balance of plant equipment, our extensive experience includes both new and retrofit applications.

B&W’s selective catalytic reduction (SCR) technology provides our customers with a proven and competitive suite of NOx control solutions.

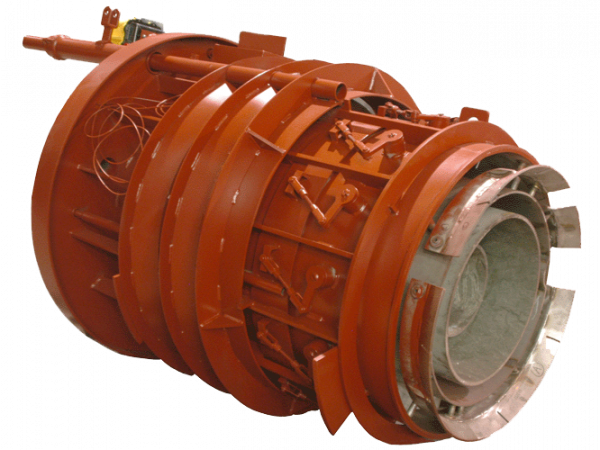

High performance SCR systems require thorough blending of ammonia with the NOx-laden gas. Our ammonia injection grid and mixing systems deliver the high performance required over the entire load range, simply and robustly, with minimal maintenance requirements.

Our reference plant installations include applications that utilize fossil and biomass fuels, as well as municipal waste. Our vast experience allows us to anticipate and control the potential effects of increased SO2 production, increased pressure drop, or ammonia slip.

Through our array of SCR reactor and flue design options, we can match our overall system design to the available space on site.

In certain applications, B&W’s selective non-catalytic reduction (SNCR) technology can be deployed as a relatively low capital cost solution.

Our goals are to maximize NOx control performance while optimizing chemical utilization with low reagent consumption and the lowest levels of reagent slip. We utilize both predictive and scale modeling techniques to assure optimum gas flow distribution to achieve this goal.

Low NOx Burners & Overfire Air Ports

Additional NOx reduction can be achieved by integrating low NOx burners and staged combustion (overfire air) into the overall system. Since 1971, B&W has sold low NOx combustion systems for more than 120,000 MW of generating capacity (more than 8,000 burners) in both new and retrofit boiler applications. Our low NOx burner technology has been successfully applied to a broad range of B&W and non-B&W units with varying fuel characteristics and boiler arrangements.

We pioneered the development and application of NOx ports and air staging as a NOx emissions control technique. Combined with our other low NOx technologies, such as burners and selective catalytic reduction systems, overfire air systems can be installed on all wall-fired and corner-fired steam generators and are part of an overall NOx reduction strategy.

BREF Solutions

The European BREF regulations will require all large combustion power plants to comply with stricter air emissions limits by 2022. This includes limits on mercury (Hg), sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter (PM).

Babcock & Wilcox (B&W) has the proven technical experience, know-how and responsiveness to help you lower air emissions to acceptable levels. Our air emissions regulations experience along with extensive boiler design and combustion knowledge makes us uniquely qualified to consider how each environmental solution will affect performance and operation of existing power plant equipment.