VoluMix™ System

Proper, turbulent mixing of the flue gases in the boiler furnace provides a better combustion process and burn-out in the gas phase.

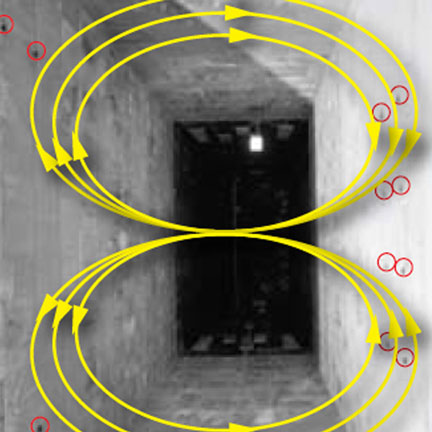

With the B&W Volund VoluMix™ system, all of the primary air passes through the narrow gap between the grate bars, creating a strong, turbulent combustion zone. The system is installed at the inlet of the first pass.

VoluMix™ ensures very low carbon monoxide (CO) and total organic carbon (TOC) content in the flue gas.

Advantages of VoluMix include:

- Good mixing and combustion conditions in the furnace – gas-phase burnout

- Staged combustion makes it possible to reduce the formation of fuel NOx

- Avoidance of hot spots in the furnace and boiler which would speed up corrosion

- Obtaining turbulent conditions for optimum burnout–low CO levels

- Uniform temperature and velocity distribution in the convection passes to maximize heat transfer and residence time

- Basis for low excess air resulting in high overall thermal efficiency

- Eliminates the need for flue gas recirculation, saving fan investment cost, as well as operation and maintenance costs