Leading Clean Power Production Systems for the Petrochemical & Refining Industry

Babcock & Wilcox has served the petrochemical & refining industry for many years by providing a wide range of clean power production technologies and aftermarket support services including parts, equipment upgrades and field engineering.

Services & Engineered Solutions for the Petrochemical and Refining Industry

Babcock & Wilcox has served the oil and gas industry for many years. From boilers for FCC gas cooling, carbon monoxide (CO), waste heat (WH) and auxiliary steam, to boiler cleaning systems, petroleum coke handling and electrostatic precipitators, our custom engineered technology solutions add value to your refinery operations. In addition, we can provide key turnaround scope development, field engineering support and construction services.

- Power and steam generation

- Air, water and gas treatment

- Material handling

- Turnaround projects and services

- Technical field support and advisory services

Services & Engineered Solutions

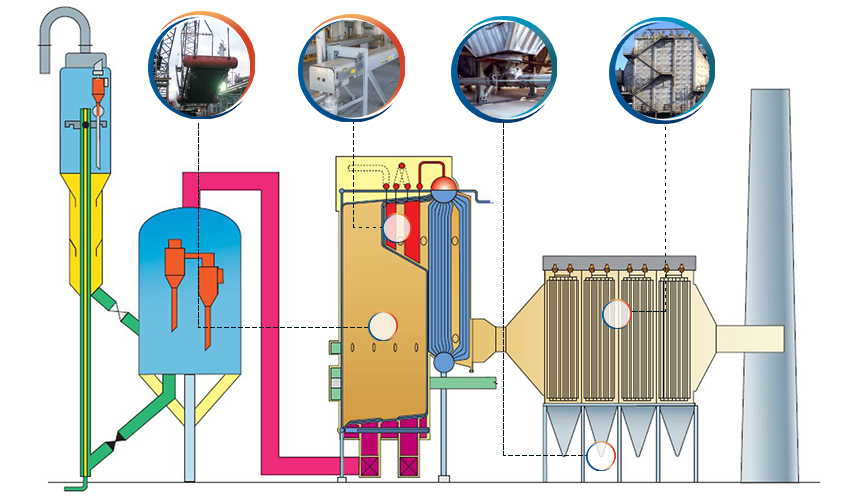

Hover on a pulsating dot within the graphic to explore B&W thermal and environmental solutions.

Boiler aftermarket (upgrades, parts, services and construction)

Diamond® Power boiler cleaning

Catalyst dust and pet coke handling

Electrostatic precipitators and aftermarket solutions

Boiler aftermarket (upgrades, parts, services and construction)

Diamond® Power boiler cleaning

Catalyst dust and pet coke handling

Electrostatic precipitators and aftermarket solutions

Wet Gas Scrubbers for Fluid Catalytic Cracking (FCC) Emissions Control

Developed by ExxonMobil in the 1970s and now licensed by B&W, wet gas scrubbing technology removes particulates and sulfur dioxide (SO2) by intimate mixing of the flue gases with an aqueous scrubbing liquid. The technology can also be enhanced to meet tighter restrictions on nitrogen oxides (NOx) or particulate. This well-proven technology provides refiners with numerous advantages for maximum FCC unit availability.