Search Results

Your search results for "the" are below. Click tabs to filter by type.

Tanjung Jati Case Study

This installation of environmental equipment at the Tanjung Jati power plant includes low NOx burners, a wet FGD system and electrostatic precipitators.

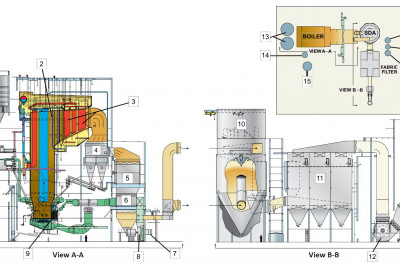

Coal-fired internal recirculation circulating fluidized-bed (IR-CFB) boiler from outlet of coal bunkers to outlet of tubular air heater.

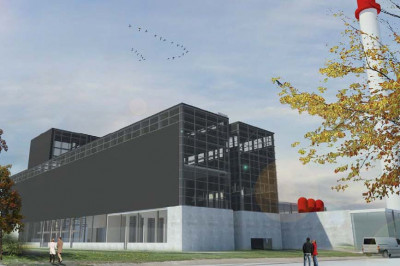

View Web PageCombined heat and power plant will provide process steam for an adjacent malt plant and will normally generate approximately 56 MW net of electricity for the regional transmission grid.

View Web PageB&W installed DRB-4Z® low NOx burners and overfire air, a selective catalytic reduction (SCR) NOx removal system, a dry flue gas desulfurization (FGD) system, a pulse jet fabric filter particulate collector and a powdered activated carbon injection system for mercury removal.

An explosion during a maintenance outage on February 17, 1999, destroyed the original Hawthorn Unit 5 boiler. In August 1999, B&W was released to design, supply, erect and commission a complete replacement boiler on an accelerated schedule. The new boiler began generating electricity in June 2001, only 22 months from project commencement.

View Web PageB&W was selected to design a Vølund® waste-to-energy (WtE) combustion system and boiler for Shenzhen Energy Environmental Engineering Co. The 5,600 tons per day plant is among the world’s largest and was completed in 2020.

View Web PageCopenhagen’s state-of-the-art Amager Bakke sets new standards for environmental performance, energy efficiency and waste treatment capacity.

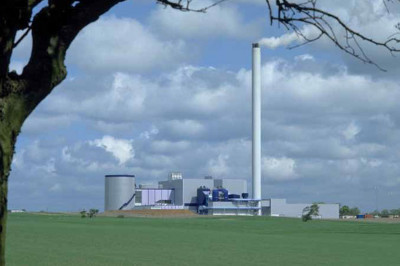

View Web PageBabcock & Wilcox Renewable (B&W) designed, manufactured and commissioned two biomass boilers for the Skærbækværket power plant in Denmark. The project allows the combined heating and power plant to supply approximately 60,000 households with clean and reliable district heating and electricity while reducing carbon emissions.

View Web PageMultifuel-Fired CHP Plant Case Study

Måbjergværket is the first CHP plant in Denmark to use a fuel combination consisting of waste, wood chips, straw and natural gas. Måbjergværket supplies the approx. 55.000 inhabitants of the cities of Struer and Holstebro with direct heating.

View Web PageNew combined heat- and power-producing WtE line designed for burning 10 tonnes of waste per hour increases energy efficiency from 70% to 99%.

View Web Page