Bridging the gap between soaring energy demand and readily available resources.

There is an urgency to deploy affordable, reliable technologies to meet the growing energy demand – quickly, responsibly, and using readily available fuel for domestic energy security. Throughout our history, we have met this challenge. And we continue this legacy with BrightLoop™ technology.

BrightLoop offers a scalable alternative for baseload steam generation to support the rapidly growing demand for generating capacity.

BrightLoop can generate steam using a wide range of feedstocks including:

- Coal

- Natural Gas

- Biomass

- Waste-derived fuels

The Process

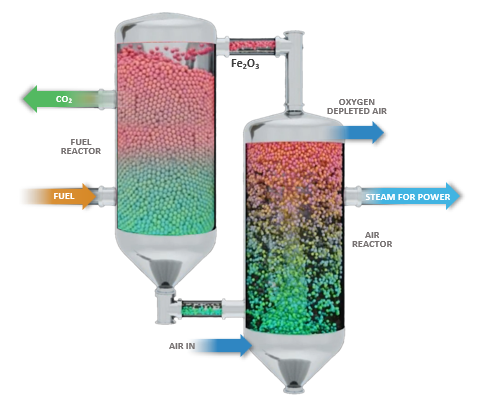

The BrightLoop technology is a novel chemical looping process that is based on the oxidation and reduction of an oxygen carrier particle. The feedstock reacts with oxygen-carrier particles in a fuel reactor, forming reaction products which are predominantly CO2, while reducing the oxygen-carrier particles.

The BrightLoop technology is a novel chemical looping process that is based on the oxidation and reduction of an oxygen carrier particle. The feedstock reacts with oxygen-carrier particles in a fuel reactor, forming reaction products which are predominantly CO2, while reducing the oxygen-carrier particles.

The oxygen-carrier particles are then transported to an air reactor where they are regenerated with air back to their original state. The products of these reactors are predominantly an oxygen-depleted air stream with concentrated nitrogen. The fully regenerated particles are then returned to the fuel reactor to continue the “loop” process. The fuel reactor uses moving-bed technology, which facilitates the complete conversion of the fuel while the air reactor uses fluidized-bed technology which also acts as a transport mechanism for the particle to the top of the fuel reactor.

Gaseous products generated in each reactor are cooled using various heat exchangers including steam generators that produce the steam and cleaned of undesirable emissions using typical B&W environmental control technologies.