BrightLoop for Syngas Production

Syngas, or synthetic gas, is a mixture of carbon monoxide (CO), and hydrogen (H2), often with some carbon dioxide (CO2) and methane (CH4), or nitrogen (N2) depending on the production method. Syngas is utilized as the building block of many fuels and chemicals that are utilized every day in refining, transportation, fertilizers and plastics. Traditional methods of syngas production utilize fossil fuels as feedstock and create excess CO2 in the process which leads to higher life cycle emissions, while emerging technologies that utilize renewable feedstocks such as biomass or waste struggle with feedstock variability and tars.

Syngas, or synthetic gas, is a mixture of carbon monoxide (CO), and hydrogen (H2), often with some carbon dioxide (CO2) and methane (CH4), or nitrogen (N2) depending on the production method. Syngas is utilized as the building block of many fuels and chemicals that are utilized every day in refining, transportation, fertilizers and plastics. Traditional methods of syngas production utilize fossil fuels as feedstock and create excess CO2 in the process which leads to higher life cycle emissions, while emerging technologies that utilize renewable feedstocks such as biomass or waste struggle with feedstock variability and tars.

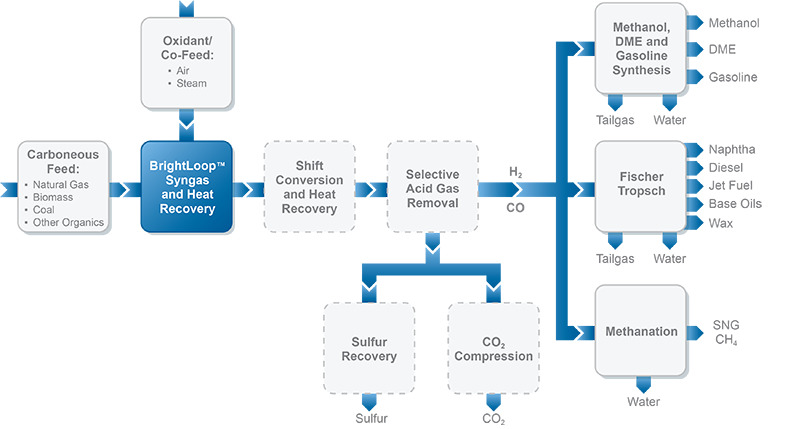

BrightLoop Syngas produces high-quality syngas from both fossil and renewable feedstocks, with reduced CO₂ levels and enhanced tar cracking, thereby offering tailored solutions for a wide range of industries. By utilizing a novel iron-oxide TranspO2rt™ oxygen carrier particle, BrightLoop separates the conversion of the fuel from air. The particle and the feedstock react as they flow downward in the fuel reactor and exit the fuel reactor as syngas while yielding transport particles in their reduced oxidation state. The particles are then transported to the air reactor to be fully regenerated and recycled back to the top of the fuel reactor. The oxygen-depleted air leaves the loop at the top of the fuel reactor in a separate stream hence preventing the addition of impurities in the syngas product stream. The process can be tailored to a variety of feedstocks, and dial in required steam to yield the desired H2 to CO ratio in order to support downstream process needs.

Benefits

When using BrightLoop technology for syngas production, several benefits can be realized, including:

- Low or negative carbon fuels

- Feedstock variation tolerance

- Less/smaller unit operations

- Cracks tars

- No/less pretreatment of biomass

- Low CO2 generation

- Adjustable H2/CO ratio up to 2

...all which ultimately lead to lower overall CAPEX.

BrightLoop technology’s unique features allow it to be paired with traditional equipment to create lower carbon products with a streamlined and less costly process. BrightLoop technology’s ability to crack tars and maintain consistent syngas quality with varying feedstocks present a novel solution for low-carbon fuels markets such as methanol, ammonia, sustainable aviation fuel and fertilizers.