From The Leader in Clean Power Production Technologies

Tanjung Jati Case Study

Tanjung Jati B Units 1 and 2

PT Central Java Power (Sumitomo Corporation)

Jepara, Jawa Tengah, Republic of Indonesia

Plant Owner

PT Central Java Power (Sumitomo Corporation)

Plant Name

Tanjung Jati B

Location

Jepara, Jawa Tengah,

Republic of Indonesia

EPC Contractor

Sumitomo Corporation

B&W Consortium Scope

B&W subsidiaries, in consortium with units of Black & Veatch, supplied:

- Complete boiler island for two coal-fired units, from ship unloaders to the stack, including:

- coal handling with stacker/reclaimers and conveyors

- structural steel

- coal silos

- ash handling

- limestone and gypsum handling

- environmental equipment

- electrical, including motor control centers, switchgear, and power/control wiring

- instrumentation, including stack emissions monitoring system

- auxiliary piping systems

- technical advisory services for erection technical advisory services during startup and commissioning

Boiler Specifications

- Boiler type: Pulverized coal-fired radiant drum boiler (RB Carolina-Type)

- Design fuel: Indonesian low sulfur coal

- Capacity: 2 X 660 MW net

- Steam flow: 5,099,000 lb/h (642 kg/s)

- Superheater outlet pressure: 2527 psig (17.4 MPa)

- SH/RH outlet temperature: 1006/1001 F (541/538 C)

Environmental Equipment

- DRB-XCL® low NOx burners

- Wet flue gas desulfurization (FGD) system, including absorbers, limestone unloading and handling, reagent preparation and dewatering system

- Electrostatic precipitators

Other Equipment Supplied by B&W

- B&W Roll Wheel® pulverizers with DSVS® rotating classifiers Sootblower boiler cleaning system by Diamond Power International, Inc. (DPII), a B&W subsidiary

- Bottom ash system supplied by Allen-Sherman-Hoff, a division of DPII

Contract Order: 1995

Commercial Operation: 2006

Project Facts

- Power purchase agreement signed between PT Perusahaan Listrik Negra (Persero) and PT CEPA Indonesia – September 1994

- Project Commencement – April 1997

- Project was suspended for five years due to Asian currency crisis in 1998. Resumed in 2003 and was completed under Sumitomo’s leadership.

- The limestone wet FGD system utilizes seawater for makeup.

Environmental equipment at the Tanjung Jati power plant includes low NOx burners, wet FGD system, and electrostatic precipitators.

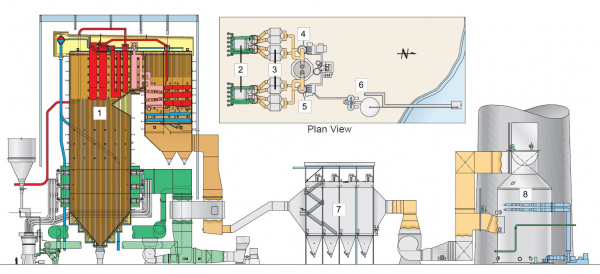

Sectional Side and Plan Views of Tanjung Jati B Power Plant