From The Leader in Clean Power Production Technologies

Shenzhen Energy Environmental Engineering — Shenzhen, China

Success Story

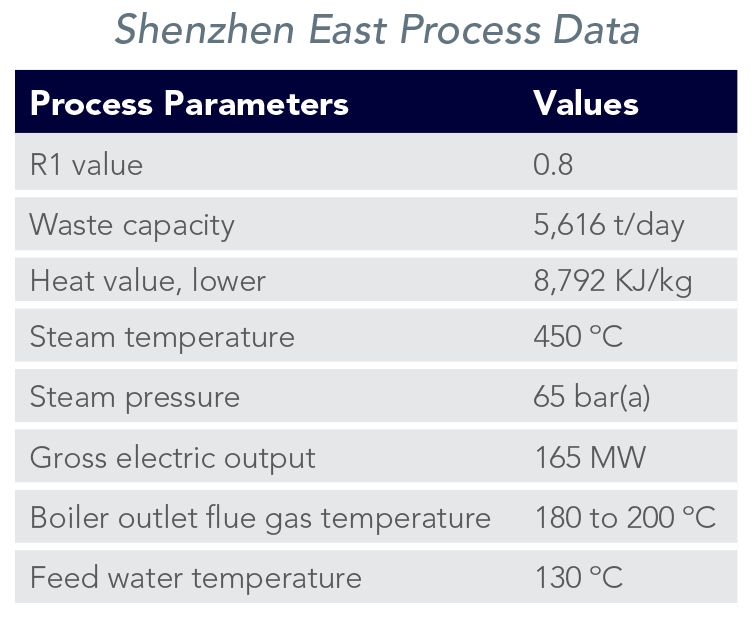

Babcock & Wilcox Renewable (B&W) was selected to design a Vølund® waste-to-energy (WtE) combustion system and boiler for Shenzhen Energy Environmental Engineering Co. Ltd. in Shenzhen, Guangdong Province, China. The 5,600 tons per day plant is among the world’s largest and was completed in 2020. Its capacity handles approximately one-third of the waste generated by Shenzhen’s 20 million inhabitants every year.

Sustainable energy

With continuous economic growth in China and throughout Asia, there is a growing demand for reliable, sustainable and clean renewable energy.

B&W supplied the Vølund equipment for the new WtE plant in Shenzhen including a DynaGrate® combustion system, hydraulics burners and other boiler components. The plant’s circular building was designed by Danish architects Schmidt Hammer Lassen and is set amongst lush green hills in suburban Shenzhen. The plant is an important showcase of the most advanced technology for environmentally friendly energy production in China. The project is developed and implemented in partnership with our licensee, Beijing China Science Runyu Environmental Technology Co. Ltd.

B&W’s scope of supply

- Six DynaGrate combustion grates

- Boiler design

- Feeding pusher

- Charging system design

- Hydraulic system

- Burners and other boiler components

- Control concept

- Construction and commissioning advisory assistance

DynaGrate technology

The DynaGrate systems for the plant were produced at the Vølund manufacturing facility in Esbjerg, Denmark. Each grate was shipped to China in sixteen sections and assembled onsite.

The DynaGrate modular system is delivered as one or two combustion lanes depending on the size of the plant. For this project the grate has two lanes and each combustion lane is divided into four sections, with a total capacity of 39 t/h.

Optimized combustion

With this grate, plant operation is not interrupted by melting metals, thereby increasing operational time. The mechanical wave movement of the DynaGrate design breaks-up the waste layer on the grate causing thorough agitation and thereby superior combustion conditions. This results in very low unburned content (total organic carbon [TOC]) in the bottom ash.

Unlike other types of grates, there is no physical contact between moving grate components. This unique design limits wear and minimizes the mechanical forces internally in the grate. The mechanical design of the DynaGrate system is developed to increase plant availability and lower operation and maintenance costs.

The DynaGrate combustion grate is designed to reduce maintenance costs compared to classic forward- and backward-reciprocating grates, and to increase availability due to low exchange rates of grate elements. For instance, the driving mechanism is situated on the outside of the grate, keeping it from exposure of the destructive internal furnace environment and offering easy access for maintenance. To accommodate possible future increases in heat values from the local waste, the DynaGrate combustion grates at Shenzhen East are designed to allow for an optional future upgrade to a water-cooled grate system.

The inclusion of our computational fluid dynamics (CFD)-designed VoluMix™ overfire air system helps to reduce CO and TOC to a minimum in the gas phase.