Search Results

A major industrial petrochemical plant in South Africa needed to significantly reduce nitrogen oxides (NOx) emissions to comply with the country’s latest air quality monitoring, management and control standards. The National Environment Management: Air Quality Act required that levels be reduced to 750 mg/Nm3 for each combustion installation with a thermal rating of more than 50 MW. With levels rated at 1100 mg/Nm3, plant operators began to look at options to help achieve compliance.

View Web PageWaste Wood-Fired Biomass Power Plant Case Study

This new biomass plant will be capable of processing waste wood, including contaminated wood and fuel containing metals, with no pre-treatment required. The plant will generate 40 MW of green electricity, which is enough to supply 78,000 homes.

View Web PageBulleh Shah Packaging – Pakistan Biomass Case Study

Under a licensing agreement, B&W Vølund has supplied technology to a biomass fired energy plant at the Bulleh Shah Packaging Limited paper factory. The fuel consists of residues from local wheat straw, cotton stalks, corn, rice and river grass. The plant’s steam data will be 150 t/h at 530 degrees and 98 bara: enough to secure stability in the supply of steam and power to the factory. A reliable supply of energy is rare in Pakistan. It can be both expensive and challenging for the factory when p

View Web PageSan Juan Generating Station Case Study

Babcock & Wilcox (B&W) provides cost-effective control of particulate emissions and opacity with our proven pulse jet and reverse air fabric filter technologies. We have provided some of the largest fabric filters in the world. Innovative design features such as long bag technology, integral gas and dust distribution devices, as well as online maintenance capability provide benefits of increased reliability while achieving lower emissions.

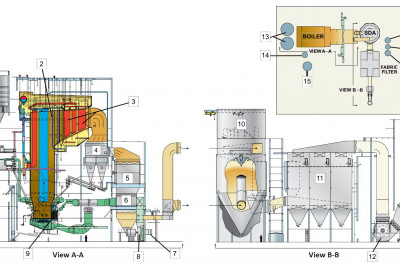

The I/S REFA waste incineration plant in Nykøbing Falster, Denmark is jointly owned by 13 municipalities. The company collects and treats all kinds of waste from households and industries on the two islands of Lolland and Falster, a total of about 200,000 tons/year. The majority of the waste is either combusted or recycled.

View Web PagePrairie State Generating Company Case Study

The boilers burn coal from a mine adjacent to the power plant. Electricity produced is dedicated to supply eight Midwestern-based public power utilities serving customers across nine states. The design of these boilers was modified to adapt to the requirements of the Prairie State Energy Campus project, including a change in fuels from Powder River Basin sub-bituminous coal to Illinois bituminous coal.

Alunorte Case Study

The steam produced by the CFB boiler, in conjunction with the existing steam generation units, will fulfill the needs of the alumina production process in a safe, reliable and efficient manner.

View Web PageTanjung Jati Case Study

This installation of environmental equipment at the Tanjung Jati power plant includes low NOx burners, a wet FGD system and electrostatic precipitators.

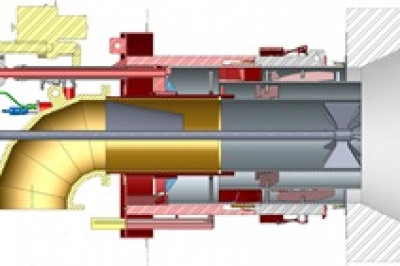

Coal-fired internal recirculation circulating fluidized-bed (IR-CFB) boiler from outlet of coal bunkers to outlet of tubular air heater.

View Web PageCombined heat and power plant will provide process steam for an adjacent malt plant and will normally generate approximately 56 MW net of electricity for the regional transmission grid.

View Web Page