From The Leader in Clean Power Production Technologies

Alunorte Case Study

Alunorte CFB Steam Generator

Alumina do Norte do Brasil S.A.

Barcarena, Para, Brazil

This project was supplied by HPB Engenharia e Equipamentos Ltda. (HPB), a licensee of Babcock & Wilcox (B&W).

Contract Order:

2006

Commercial Operation:

2008

HPB Scope of Supply

Coal-fired internal recirculation circulating fluidized-bed (IR-CFB) boiler including:

- Structural steel

- Fans and motors

- Tubular air heaters

- Economizer

- Multi-cyclone dust collector (MDC)

- Ash recycle/reinjection system

- Limestone injection system

- Limestone silo

- Startup burners

- Refractory lined lower furnace with erosion protection at the Reduced Diameter Zone (RDZ) transition

- Fluid bed ash coolers

- Bed drain system including screws, screeners, crushers, belt conveyor and bucket elevators

- Multi-cyclone dust collector screws

- Flues and ducts

- Segmented U-beam primary particle collectors with watercooled support system

- Coal feeders and bunkers

- Blowdown tanks

- Instrumentation and controls

Environmental Equipment

Boiler Specifications

- Boiler type: Internal Recirculation CFB design

- Design fuel: Bituminous coal

- Startup fuel: Light (diesel) oil

- Capacity: 256 MWt

- Steam flow: 750,000 lb/h (94.5 kg/s)

- Steam pressure: 1536 psig (10.6 MPa)

- Steam temperature: 925F (496C)

Project/Boiler Facts

- The steam produced by the CFB boiler, in conjunction with the existing steam generation units, will fulfill the needs of the alumina production process in a safe, reliable and efficient manner.

- The addition of limestone to the circulating bed reduces sulfur dioxide (SO2) emissions from the boiler.

- Low furnace temperatures and staged combustion limit nitrogen oxides (NOx) emissions.

- Unique two-stage solids collection system using U-beams and MDC provides superior collection efficiency. The recycling of solids collected by the MDC improves combustion efficiency and limestone utilization.

- The U-beam and MDC solids collection system requires significantly less maintenance than hot cyclones.

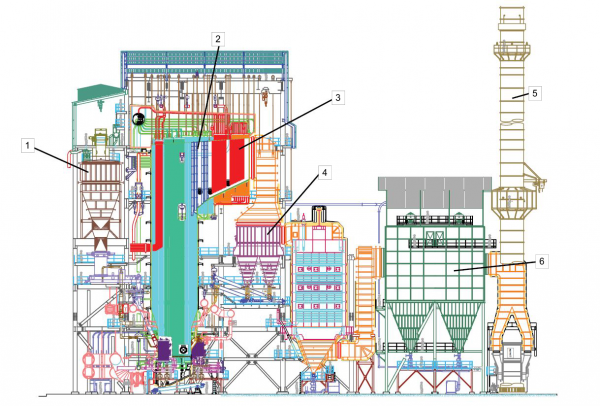

- RDZ design with silicon carbide tiles at the top edge of the furnace refractory is used to minimize tube erosion at the interface. Side View of the Alunorte CFB Steam Generator and Pulse Jet Fabric Filter.

Side View of the Alunorte CFB Steam Generator and Pulse Jet Fabric Filter

1: Coal silo

2: U-beam particle separators

3: Superheater

4: Multi-cyclone dust collector

5: Stack

6: Pulse jet fabric filter