From The Leader in Clean Power Production Technologies

B&W’s DRB-XCL® Burners Reduce NOx in South Africa

Project Description

A major industrial petrochemical plant in South Africa needed to significantly reduce nitrogen oxides (NOx) emissions to comply with the country’s latest air quality monitoring, management and control standards. The National Environment Management: Air Quality Act required that levels be reduced to 750 mg/Nm3 for each combustion installation with a thermal rating of more than 50 MW. With levels rated at 1100 mg/Nm3, plant operators began to look at options to help achieve compliance.

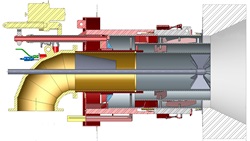

After an extensive review of commercially available technologies, Babcock & Wilcox’s (B&W’s) DRB-XCL® low NOx burners were selected to help meet the new emissions limits for what would be one of the first NOx abatement projects in the country.

Technology Selection

B&W has more than 50 years of experience in installing low NOx combustion systems for both new and retrofit boiler applications around the world. This includes the design and supply of more then 10,000 burners.

Computational fluid dynamics modeling of plant-specific variables and desired outcomes helped fine tune the design for optimum NOx performance and unit efficiency.

From among its available burner designs, B&W’s DRB-XCL type was chosen as best suited for the plant’s unique application. Criteria included:

- Fuel (heating value, moisture, sulfur)

- Boiler and burner configuration

- Furnace size

- Target emissions reduction requirements

- Capital and O&M costs

- Reliability

- Outage/shutdown cycle

- Future fuel flexibility

One of the main advantages of B&W’s DRB-XCL burner is that the internals of the burner are customizable and, therefore, burner performance can be optimized in situ by adjusting components. This enabled priority to initially be given to stable operation, and upon site testing, burner internals could be adjusted incrementally until the optimum balance between stability and minimum NOx was achieved.

In addition to its customizable features, B&W’s DRB-XCL burner was preferred due to its ability to perform with low-grade, low-volatile, high-ash fuel without the need for overfire air, as the furnace geometry prevented this.

Scope

- Engineering design, manufacture and commissioning support for 42 DRB-XCL burners: 6 burners per boiler on 7 boilers

- Supports and actuators

- FPS® oil ignitors and flame scanners

- Plant personnel training

B&W’s DRB-XCL burners were installed on non-B&W boilers originally supplied in 1970, each producing approximately 150 t/hr of steam.

Results

During the final performance test, NOx was reduced by more than 40 percent of the targeted emissions level

|

NOx LEVELS |

|

|

Initial/Baseline |

1100 mg/Nm3 |

|

Target |

750 mg/Nm3 |

|

Final Performance |

470 mg/Nm3 |

This was one of the first NOx abatement projects successfully implemented in South Africa, and the first to achieve a NOx emissions result well below the minimum emissions standard requirements.

![]() Recognition

Recognition

The project was recognized with the 2019 South African National Energy Association (SANEA) Energy Project of the Year Award. The award recognizes projects that positively contribute to the South African energy environment or bring international credibility to the country through leadership, innovation, initiative and vision.