From The Leader in Clean Power Production Technologies

Prairie State Generating Company Case Study

Prairie State Generating Company

Prairie State Energy Campus

Washington County, Illinois

Plant Owner

Prairie State Generating Company (PSGC)

Plant Name

Prairie State Energy Campus

EPC Contractor

Bechtel Power Corporation

Location

Washington County, Illinois

Contract Order: 2007

Planned Commercial Operation

- Unit 1, 4th quarter, 2011

- Unit 2, 3rd quarter, 2012

B&W Scope

- Supercritical, spiral wound coal-fired boilers

- Construction advisory services

- Startup and commissioning advisory services

Boiler Specifications

- Boiler type: Pulverized coalfired SWUP™ supercritical boiler

- Design fuel: Illinois bituminous coal

- Capacity: 2 X 800 MW (net)

- Main steam flow: 5,910,150 lb/h (745 kg/s)

- Superheater outlet pressure: 3780 psig (26 MPa)

- SH/RH outlet temperature: 1055/1055 F (568/568 C)

Environmental Equipment

- High velocity DRB-4Z® low NOx burners

- Selective catalytic reduction (SCR) NOx removal system

Other Equipment Supplied by B&W

- B&W Roll Wheel® pulverizers, Series 98, with DSVS® rotating classifiers and Auto-Spring™ loading system

- Sootblower boiler cleaning system

- Powerclean™ intelligent sootblowing system

Project Facts

- The boilers were originally designed for another project and were partially fabricated when that project was canceled.

- The design of these boilers was then modified to adapt to the requirements of the Prairie State Energy Campus project, including a change in fuels from Powder River Basin sub-bituminous coal to Illinois bituminous coal.

- The boilers burn coal from a mine adjacent to the power plant.

- Electricity produced is dedicated to supply eight Midwestern-based public power utilities serving customers across nine states.

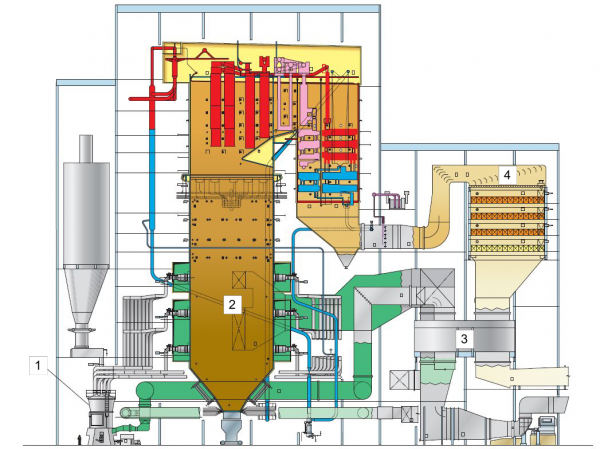

Sectional Sideview of Prairie State Units 1 and 2.

1: B&W Roll Wheel pulverizers

2: Furnace with spiral-wound tubes

3: Air heater

4: Selective catalytic reduction (SCR)