Search Results

Your search results for "the" are below. Click tabs to filter by type.

Babcock & Wilcox (B&W) has extensive experience with boiler conversions and modifications, including extensive refurbishments of older recovery boilers to BFB conversion while reusing existing buildings and ancillary equipment.

View Web PageWet Flue Gas Desulfurization Systems Midwestern Case Study

The wet flue gas desulfurization (FGD) system from Babcock & Wilcox (B&W) features a combination of design components to provide a high level of reliability and removal efficiencies. These include B&W’s signature tray tower design that provides excellent gas to liquid contact and uniform flow distribution through the absorber spray zones; its patented inlet awning; interspatial headers to reduce absorber height, pump power requirements, and internal support costs; forced oxidation system; and ad

View Web PageSan Juan Generating Station Case Study

Babcock & Wilcox (B&W) provides cost-effective control of particulate emissions and opacity with our proven pulse jet and reverse air fabric filter technologies. We have provided some of the largest fabric filters in the world. Innovative design features such as long bag technology, integral gas and dust distribution devices, as well as online maintenance capability provide benefits of increased reliability while achieving lower emissions.

Chalk Point, Dickerson and Morgantown Case Study

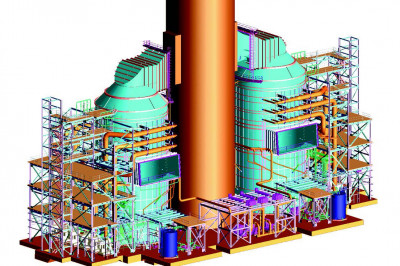

Babcock & Wilcox (B&W) supplied wet flue gas desulfurization (FGD) equipment to provide sulfur dioxide (SO2) removal efficiency of 98% of total gas flow. This design features a combination of components to provide a high level of reliability and removal efficiencies. These include a milling system, absorber towers, trays, spray headers, nozzles, mist eliminators, wash headers and forced oxidation.

View Web PageHatfield’s Ferry Station Case Study

The wet flue gas desulfurization (FGD) system from Babcock & Wilcox (B&W) features a combination of design components to provide a high level of reliability and removal efficiencies. These include B&W's signature dual tray tower design that provides excellent gas-to-liquid contact and uniform flow distribution through the absorber spray zones; its patented inlet awning; interspatial headers to reduce absorber height, pump power requirements, and internal support costs; forced oxidation system; a

View Web PageComanche Station Units Case Study

Babcock & Wilcox (B&W) dry flue gas desulfurization (FGD) systems feature a combination of design components to provide a level of reliability and sulfur dioxide (SO2) removal efficiencies that are among the highest in the industry.

Monroe Units 1, 2, 3 and 4 Case Study

The wet flue gas desulfurization (FGD) system from B&W features a combination of design components to provide a high level of reliability and removal efficiencies. These include B&W’s signature tray tower design that provides excellent gas-to-liquid contact and uniform flow distribution.

View Web PageFort Martin Case Study

The wet flue gas desulfurization (FGD) system from Babcock & Wilcox (B&W) features a combination of design components to provide a high level of reliability and removal efficiencies. These include B&W's signature dual tray tower design that provides excellent gas-to-liquid contact and uniform flow distribution through the absorber spray zones; its patented inlet awning; interspatial headers to reduce absorber height, pump power requirements, and internal support costs; forced oxidation system; a

View Web PageMitchell Station Case Study

The wet flue gas desulfurization (FGD) system from Babcock & Wilcox (B&W) features a combination of design components to provide a high level of reliability and removal efficiencies. These include B&W’s signature tray tower design that provides excellent gas to liquid contact and uniform flow distribution through the absorber spray zones; its patented inlet awning; interspatial headers to reduce absorber height, pump power requirements, and internal support costs; forced oxidation system; and ad

View Web PageBulleh Shah Packaging – Pakistan Biomass Case Study

Under a licensing agreement, B&W Vølund has supplied technology to a biomass fired energy plant at the Bulleh Shah Packaging Limited paper factory. The fuel consists of residues from local wheat straw, cotton stalks, corn, rice and river grass. The plant’s steam data will be 150 t/h at 530 degrees and 98 bara: enough to secure stability in the supply of steam and power to the factory. A reliable supply of energy is rare in Pakistan. It can be both expensive and challenging for the factory when p

View Web Page