From The Leader in Clean Power Production Technologies

Wet Flue Gas Desulfurization Systems Midwestern Case Study

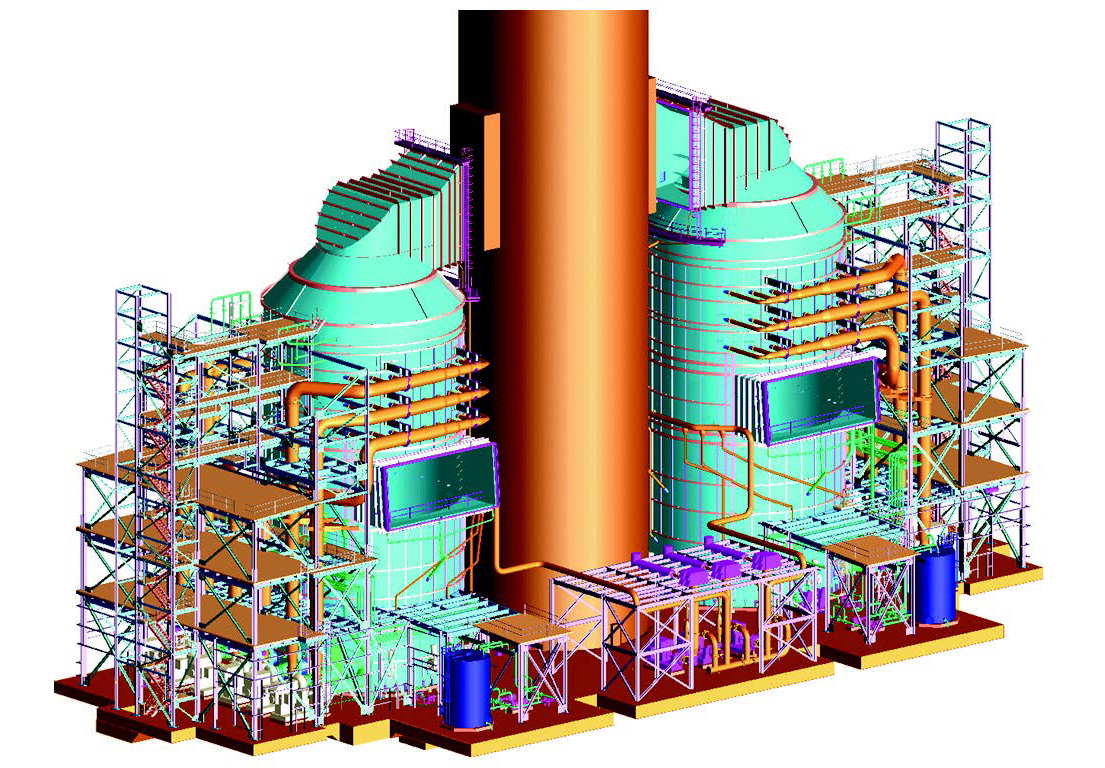

Wet Flue Gas Desulfurization Systems Units 1, 2 and 3 Midwestern

Midwestern U.S. Utility

The wet flue gas desulfurization (FGD) system from Babcock & Wilcox (B&W) features a combination of design components to provide a high level of reliability and removal efficiencies. These include B&W’s signature tray tower design that provides excellent gas to liquid contact and uniform flow distribution through the absorber spray zones; its patented inlet awning; interspatial headers to reduce absorber height, pump power requirements, and internal support costs; forced oxidation system; and advanced mist eliminators.

Boiler/Plant Information

- 3 x 676 MW

- Boiler type: Pulverized coal fired

- Design fuel: Bituminous

- Additional environmental equipment: Electrostatic precipitator (ESP) and selective catalytic reduction (SCR) system

Project Summary

- Engineering, procurement and construction of a wet flue gas desulfurization system

- System designed to remove 97% of the entering SO2 without organic acid addition

- Type: Limestone forced oxidation with gypsum byproduct

- Project awarded: April 2004

- Operational dates: December 2006, May 2007, and October 2007

- Two additional B&W absorbers scrubbing a fourth boiler at the plant.

B&W Scope

- Three wet FGD absorbers (1 per boiler)

- Three limestone milling systems (1 system per boiler)

- Gypsum dewatering system that includes four horizontal table filters (3 operating, 1 spare)

- Construction of all B&W supplied equipment through Babcock & Wilcox Construction Co., Inc. (BWCC), a B&W subsidiary

Results

The project met every engineering, fabrication and construction schedule milestone. The commissioned units have met performance guarantees.

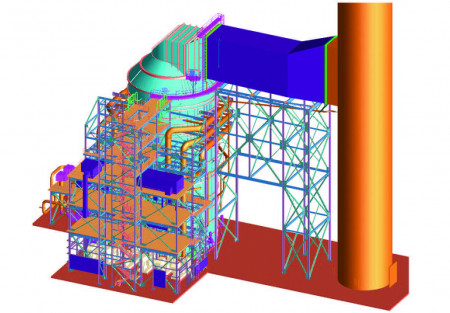

Unit 3