From The Leader in Clean Power Production Technologies

Waste-to-Energy Technology — County Meath, Ireland

Success Story

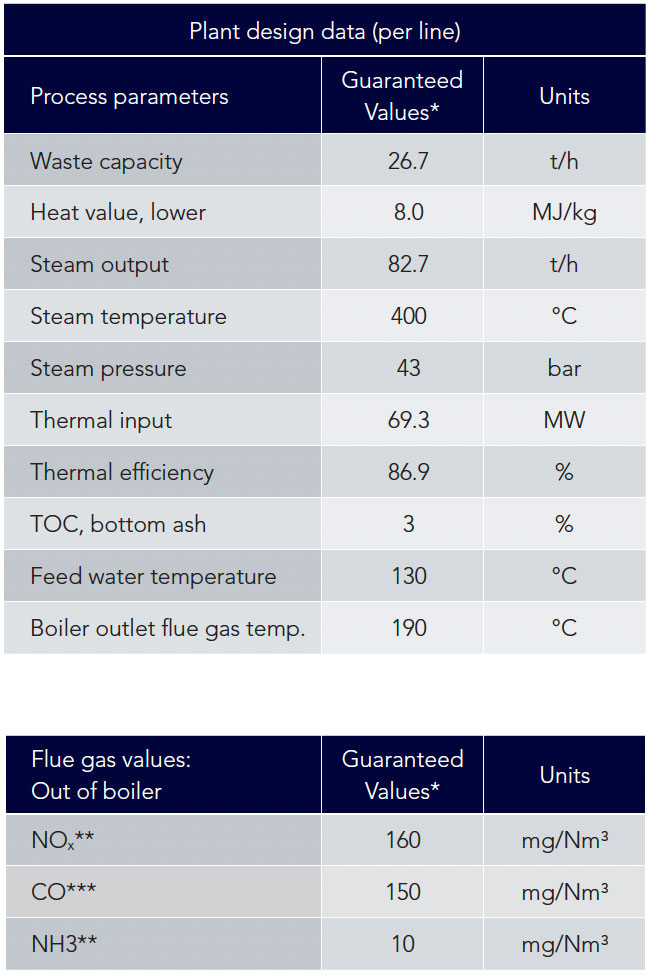

Located some 40 kilometres north of Dublin, Ireland’s first waste-to-energy plant began delivering electricity to the city’s grid in November 2011. Babcock & Wilcox Renewable (B&W) provided the boiler, combustion grate, combustion control, and selective non-catalytic reduction (SNCR) system.

The combustion system features our industry-leading Vølund® technology DynaGrate® combustion grate. The Belgian company Indaver served as the turnkey supplier in the project and operator of the plant.

Project Approach

The Meath plant was delivered on schedule as a result of our project methodology and the excellent partnership with Indaver.

B&W’s proven project execution is a result of strong project management skills and close project team cooperation with our client and subcontractors. Our project managers are certified with the International Project Management Association (IPMA).

To arrive at the most optimal technical solutions we focus on strong communication skills and project management tools. Our project teams are close units of experienced people who cover all aspects of the project with their combined knowledge and skills.

Health and Safety

In Ireland, safety is a top priority. B&W won the Safety Award for Contractor of the Month several times during the project, and the project was successfully completed without any accidents. One of the reasons are that we implemented the concept of Human Performance Improvement (HPI) which is a tool for the prevention of major incidents that could result in unnecessary costs including accidents and errors.

B&W maintains high standards with continuous training and management involvement to reinforce our primary commitment “Safety First.”