From The Leader in Clean Power Production Technologies

Renewable Energy Facility No. 2 — Florida, USA

Success Story

Overview

- Area Served: Palm Beach County, Florida

- Ownership: Solid Waste Authority of Palm Beach County

- Construction: Project awarded in 2011; construction started in 2012

- Start-up: Commercial operation began July 2015

- MSW Capacity: 3000 ton/day 1,000,000 ton/year

- Solid Waste Process Lines: 3 lines at 1000 ton/day each

Solid Waste Authority of Palm Beach County

West Palm Beach, Florida, USA

Babcock & Wilcox (B&W) and its consortium partner, KBR, Inc., engineered, designed, procured and constructed a state-of-the-art waste-to-energy (WTE) power plant for the Solid Waste Authority (SWA) of Palm Beach County in West Palm Beach, Florida.

Palm Beach Renewable Energy Facility (PBREF) No. 2 is the first WTE project of its kind in more than 20 years in the United States (U.S.).

B&W and KBR shared the design and build work scope. Commercial operation began in July 2015. B&W designed and supplied three mass burn Stirling® power boilers capable of generating up to 95 megawatts (MW) gross of electricity, enough to power the equivalent of more than 55,000 homes. In addition to the boilers, B&W provided the combustion grate system, ash systems, metals recovery systems, emissions control equipment, continuous emissions monitoring system (CEMS), automated refuse crane, and other components. KBR provided the balance of plant equipment, detailed engineering and construction services.

The emissions control system consists of spray dryer absorbers (SDA) for acid gas and sulfur dioxide (SO2) control, pulse jet fabric filters (PJFF) for particulate control, activated carbon injection to control mercury and dioxins/furans, and a selective catalytic reduction (SCR) system for nitrogen oxides (NOx) control.

The facility is capable of processing 3000 tons of municipal solid waste per day to produce electricity and significantly reduce the amount of waste sent to the county’s landfill. The project scope includes the installation of a metals recovery system to maximize the recovery and recycle of aluminum, steel and other metals.

The new plant is located on 24 acres adjacent to the SWA’s existing WTE plant, PBREF No. 1, which was also designed and built by B&W.

PBREF No. 2

Details/Specifications

- Boilers: 3 B&W Stirling power boilers

- Feed System: Automated refuse cranes, charging hopper, damper, watercooled feed chute, hydraulic ram feeder

- Grate Design: B&W Vølund® DynaGrate® traveling grate

- Primary Fuel: Unprocessed municipal solid waste

- Auxiliary Fuel: Natural gas

- Steam Capacity: 284,400 lb/h (per boiler)

- Electric Power Capacity: 95 MW gross; powers approximately 55,000 homes

- Flyash Removal System: by Allen-Sherman-Hoff (a B&W subsidiary)/Loibl

- Particulates: Pulse jet fabric filters

- Acid Gases (primarily sulfur and chlorine): Spray dryer absorbers (scrubbers)

- Nitrogen Oxides (NOx): Selective catalytic reduction (SCR) systems

- Mercury: Powdered activated carbon (PAC) injection

- Emissions Monitoring: Continuous emissions monitoring system (CEMS)

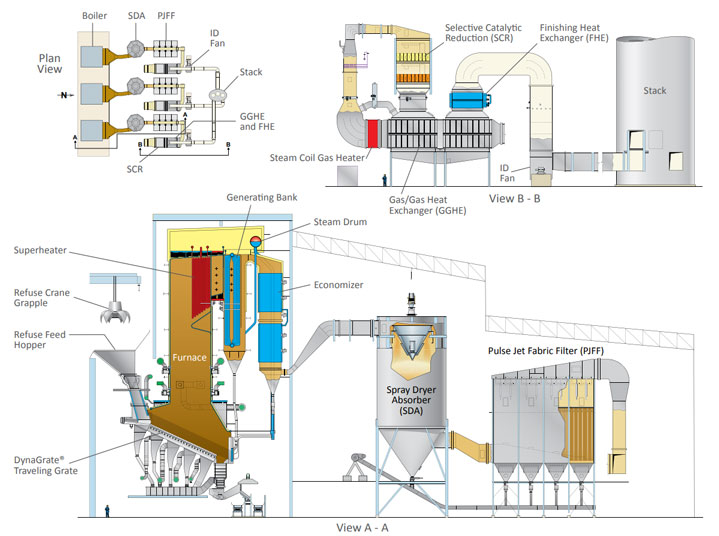

Side and plan views of the steam generation and emissions control equipment at PBREF No. 2.

Process description

Municipal solid waste (MSW), collected from homes and businesses in Palm Beach County, is delivered to transfer stations. Trucks then transport the MSW to the Palm Beach Renewable Energy Park where it is distributed to either PBREF No. 1 or the newly constructed PBREF No. 2. For PBREF No. 2, MSW is unloaded into a large pit located in the refuse building.

Crane operators, housed within the control room, manage the waste deliveries by clearing the area where the trucks drop the waste and removing any large objects which could potentially jam the processing equipment. MSW is delivered to the boilers through charging hoppers and is fed onto traveling grates where it is combusted.

The heat generated by the combustion reaction is used to boil water inside the boilers to produce steam. Steam is delivered to the facility’s turbine generator where the energy is converted to up to 95 gross MW of electricity that is sold to Florida Power & Light. Flue gases generated by the combustion reaction are then processed by the emissions control system to remove air pollutants.

The emissions control system provided by B&W is designed to remove acid gases, heavy metals, and particulates from the flue gas stream before exiting the stack. The SCR system is the first to be installed on a WTE power plant in the U.S. The cold-side SCR arrangement utilizes a unique heat recovery system to maximize power production without burning natural gas.

A continuous emissions monitoring system analyzes the flue gas to determine the concentration of regulated emissions on a continuous basis before the flue gas is sent to the stack.

Bottom and flyash byproducts of the combustion process are delivered, along with any metallic items, to an ash management building via a series of conveying equipment. A rotary magnet removes the ferrous metals and an eddy current separator removes the nonferrous metals from the ash stream to be recovered for resale on the scrap metal market. The remaining ash is collected in bunkers where it is loaded onto trucks for transporting to a landfill.