Boiler Fuel Conversions

As a leading worldwide supplier of boilers and combustion systems for a wide variety of fuels, B&W has the expertise and experience to plan, manage and execute your boiler fuel conversion project, regardless of the original boiler manufacturer.

Our fuel conversion experience is proven. We have provided more than 150 boiler conversion projects, many of which involved switching from coal or oil to 100 percent natural gas firing systems, significantly lowering environmental impact while also reducing annual fuel and plant operating costs.

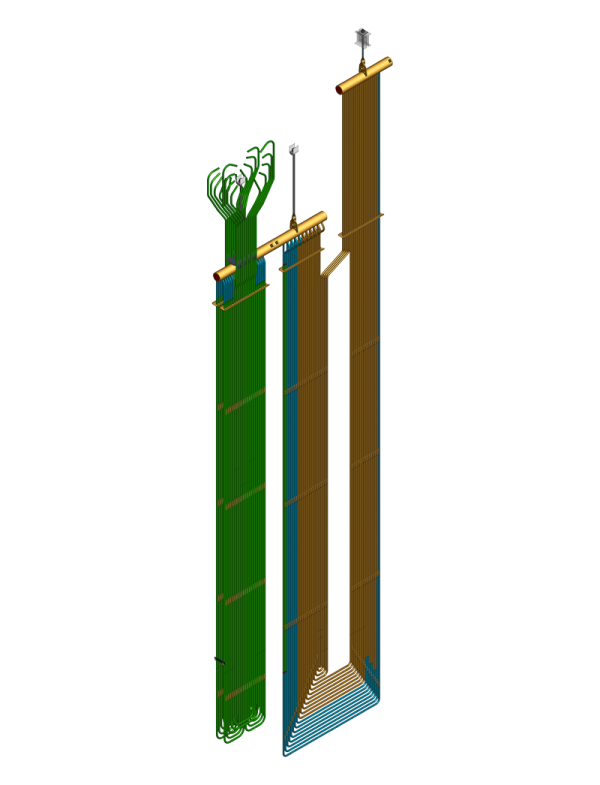

A properly designed and executed boiler fuel conversion project can be an important step in your decarbonization efforts by transitioning to lower carbon fuels, including hydrogen. B&W has also provided more than 60 industrial water-tube boilers firing hydrogen and hydrogen-blended fuels. We have performed hundreds of gas projects which have reduced the dependency on higher carbon-burning fuels.

B&W is a single-source supplier for boiler natural gas combustion systems and fuel conversion projects

B&W has provided more than 150 boiler conversion projects, many of which involved switching from coal or oil to 100 percent natural gas firing systems

Fuel Conversion Considerations

A plant may be considered for fuel switching based on many factors. Certainly, lowering carbon and other emissions is at the top of the list. But, a unit’s age, potential for retirement or a planned upgrade are also considerations. Fuel switching may also take advantage of spot fuel pricing and availability as well as environmental sustainability factors.

We can assist in comparing the costs and benefits of different scenarios to help make the best decision based on the specific needs of the plant.

For larger utility boilers, a key factor to consider is the need for plant output, including a potential for de-rate and/or increased turn-down capability. A unit’s continued usefulness might involve its ability to operate efficiently while ramping up and down based on electricity demands from the power grid, or be on standby during periods of low load.

As organizations look at their long-term forecasts, plants that operate efficiently and with high availability will play a key role in meeting future power and steam demand. As such, these plants will need to be evaluated for projects that will extend their useful life. Those projects might be targeted for efficiency improvements with coal as a fuel (burner upgrades, emissions control equipment, etc.) or for fuel switching which takes advantage of the benefits of natural gas or other low-carbon fuels.

Material upgrades may be necessary for convection pass pressure parts because gas firing can overstress tubes such as superheaters and reheaters.

Boiler Conversion Technologies

Our engineering experts can conduct a detailed analysis of all key components, systems and additions which are considered vital for fuel switching, including:

- Combustion equipment

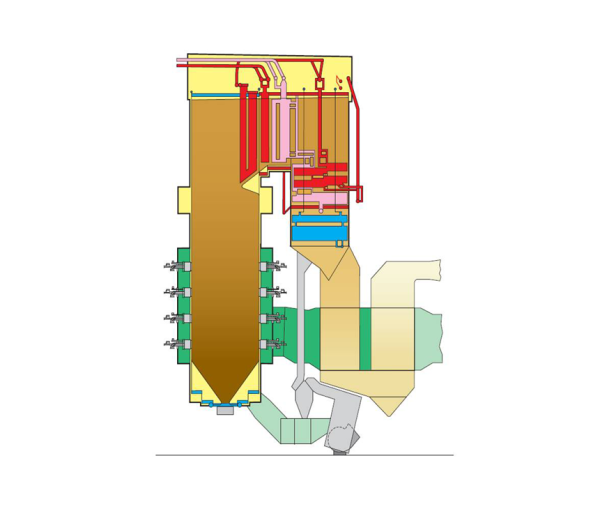

- Low-NOx burners (single or dual fuel)

- Gas and oil ignitors

- Flame scanners

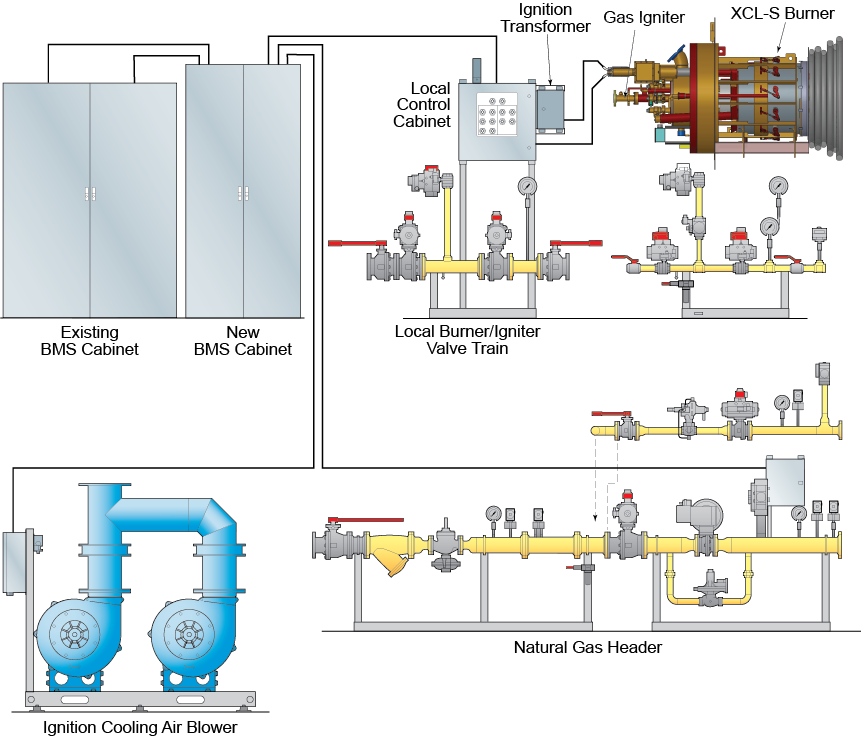

- Valve racks, fuel train assemblies, piping systems

- Air system modifications

- Boiler system

- Attemperators

- Heat transfer pressure parts (superheaters, reheaters, economizers)

- Fans

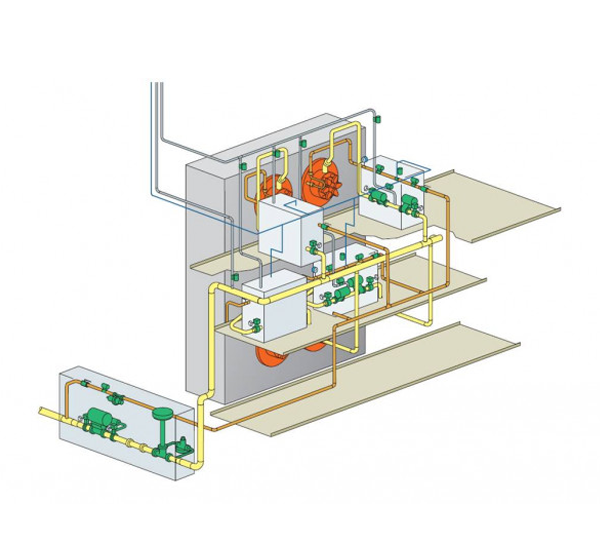

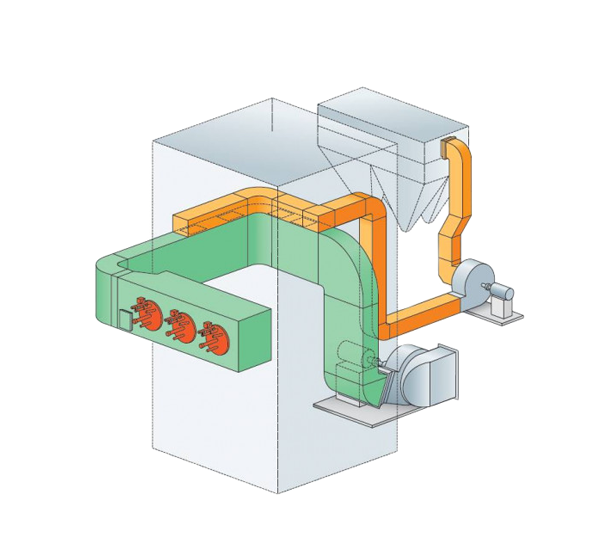

- Flue gas recirculation

- Burner management systems (BMS) and combustion controls

- Air quality control systems

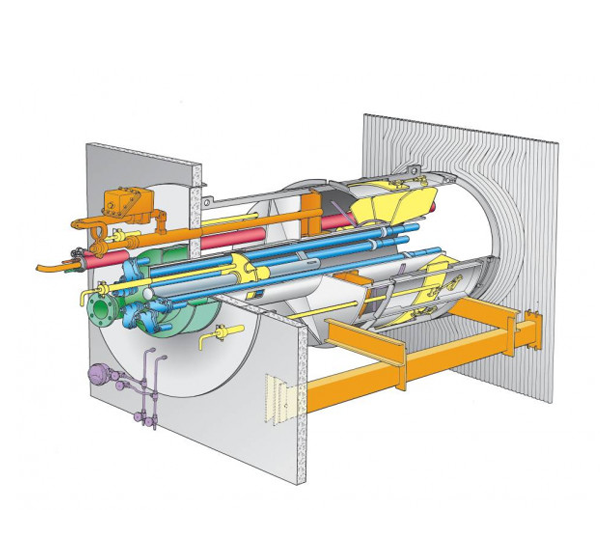

GAS FUEL TRAIN

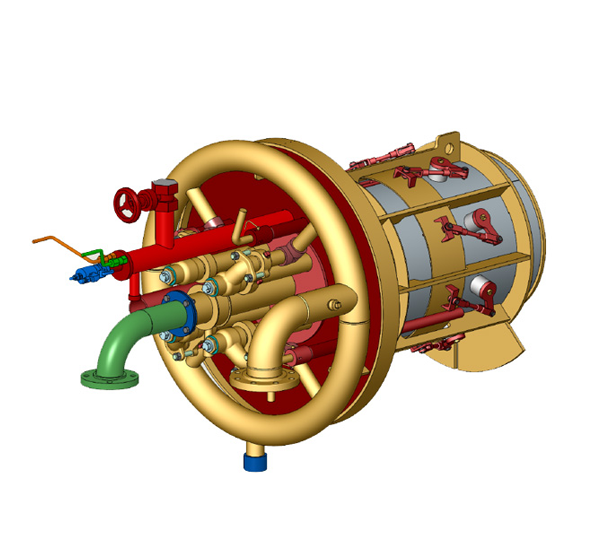

B&W XCL-S® LOW-NOX BURNER

DUAL FUEL HYDROGEN AND NATURAL GAS BURNER

FURNACE GAS RECIRCULATION

Full-scope Capabilities

In addition to equipment supply, we provide a complete range of services including design engineering, manufacturing, project management, construction, start-up and commissioning, and training.

- Engineering and feasibility studies

- Shop assembly modularization and factory acceptance testing

- Project management

- Field construction and construction management

- Aftermarket on-site support

- Start-up and commissioning

- Operator, electrical and instrumentation group training

- National Fire Protection Association, FM Global and NEC Electrical Code compliant

Our full-scope project approach allows us to fully integrate your boiler with the new combustion system.

In addition to boilers, we have experience with fuel switching projects on kilns, incinerators and heat recovery steam generators (HRSG).

We minimize project cost, schedule and unit downtime through pre-assembled modular components, plug-in type burners, staged equipment delivery for pre-outage installation and overall streamlined project management execution.

B&W has the experience and expertise to help customers evaluate the operational, technical and financial considerations associated with a potential fuel switch. As plant owners consider their options, we can assist in the evaluation of site-specific conditions and provide recommendations that represent the optimal balance of cost, schedule, performance, environmental sustainability, and long-term availability.