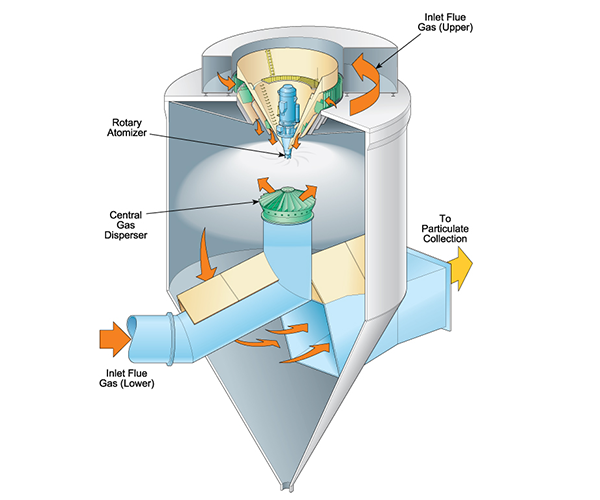

Spray Dryer Absorber (SDA)

SDA systems are designed for utility boilers typically burning low to medium sulfur coals, smaller utility applications and combined HCl and SO2 control on waste-to-energy units. B&W’s typical SDA system installations meet or exceed air quality regulations and operate at 90 to 95 percent SO2 removal efficiency, with some plants running as high as 98 percent. SO3, HCl and HF removal efficiencies are normally greater than 95 percent.

We are the exclusive North American licensee of GEA Process Engineering A/S, Denmark, for the GEA Niro SDA process. Since our first full-scale SDA in 1980 and our numerous installations since, this process remains globally recognized by the industry as the spray dry flue gas desulfurization (FGD) technology of choice.

Our SDAs feature:

- Reliable rotary atomization

- Efficient flue gas dispersion system

- High solids reagent recycle

- Innovative process control

- Control of drying conditions to minimize potential deposition and corrosion

Benefits of our SDA applications include:

- High SO2 removal

- Integral SO3, HCl, HF, heavy metals and particulate emissions reduction

- Low capital, operation and maintenance costs

- High system availability

- Low auxiliary power use

- Low fresh water consumption

- Inherent oxidized mercury emissions reduction

The unique flue gas dispersion system of the B&W SDA, coupled with the rotary atomizer, ensures a uniform distribution of slurry and provides for intimate contact with the flue gas to optimize absorption efficiency and drying in the spray chamber. For large utility boiler applications (illustrated here), flue gas enters the spray dry absorber at two locations: the roof gas disperser and the central gas disperser. Smaller, lower gas flow installations require only a roof gas disperser.

The single, centrally located rotary atomizer minimizes the potential for wall wetting and deposition, which provides optimum reagent utilization. Its abrasion-resistant construction and flexible shaft design can tolerate imbalances and provides reliable, continuous operation between scheduled maintenance.

Standard + Customizable

Standard designs with customizable options

B&W uses standard SDA designs for each application. This approach provides the end user with a cost-effective, proven system for reliable operation across wide load and fuel ranges. Our proven SDA systems have been optimized to reduce long-term power and lime consumption, while plant owners benefit from lower operation and maintenance costs. Our process typically uses a dense recycle system to provide some of the lowest lime consumption rates and byproduct generation in the industry.