Quality Parts, Services and Upgrades

How do you maintain your competitive edge in today’s market? Are you operating at peak efficiency and maximizing the returns on your assets? Are you partnering with a proven boiler parts and service provider with whom you can rely on to provide ongoing maintenance support, quality replacement parts and new technologies when needed?

These are just some of the reasons to choose Babcock & Wilcox as your one-stop aftermarket supplier for your entire plant.

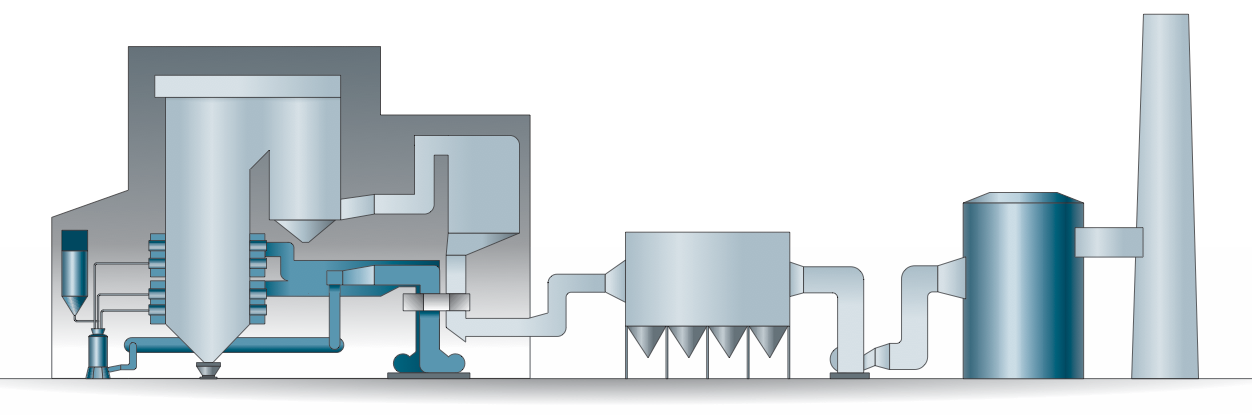

Combustion Systems

- Pulverizers

- Low NOx burners

- Igniters and scanners

- Overfire air systems

- Cyclone furnaces

Combustion Systems

- Pulverizers

- Low NOx burners

- Igniters and scanners

- Overfire air systems

- Cyclone furnaces

Boiler

- Pressure parts

- Non-pressure parts

- Diamond Power® sootblowers

- Air heaters

- Fans

Controls and Diagnostic Systems

- Advanced performance technologies

- Sootblowing controls and intelligent software

- Precipitator controls and software

- Boiler control and monitoring systems

Post-Combustion NOx Control

- Selective catalytic reduction

- Selective non-catalytic reduction

Ash and Material Handling

- Allen-Sherman-Hoff® bottom ash systems

- Allen-Sherman-Hoff® fly ash systems

Ash and Material Handling

- Allen-Sherman-Hoff® bottom ash systems

- Allen-Sherman-Hoff® fly ash systems

Particulate Control

- Electrostatic precipitators (ESP)

- Fabric filter baghouses

- Dust collectors

Mercury, Acid Gas and HAP Control

- Wet scrubbers

- Dry scrubbers

- Dry sorbent injection

- Activated carbon injection

24/7 Phone Support

From 8:00 AM to 5:00 PM ET (12:00 to 21:00 UTC), please call:

Phone: +1-330 860-1460 or toll free within North America (1-800-354-4400)

After hours: 1-800-BABCOCK (+1-800-222-2625)

For direct access to specific OEM aftermarket parts and services by product line:

Babcock & Wilcox® Boiler Parts, Environmental Parts and Service

Phone: +1-330-860-1460 or toll-free within North America 1-800-354-4400

After-Hours Emergencies Phone: 1-800-BABCOCK

Diamond Power® Sootblower Parts and Service

Phone: +1-740-687-6500 or toll-free within North America 1-800-848-5086

After-Hours Emergencies Phone: +1-800-876-9762

Allen-Sherman-Hoff® Ash Handling Parts and Service

Phone: +1-740-687-6500 or toll-free within North America 1-800-848-5086

After-Hours Emergencies Phone: +1-800-876-9762

![]()