Search Results

Basics of Electrostatic Precipitator (ESP) Operation

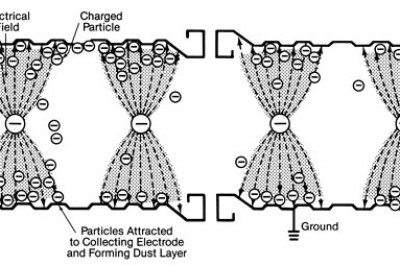

Gas velocity between the plates is also an important factor in the collection process since lower velocities permit more time for the charged particles to move to the CEs and reduce the likelihood of migrating back into the gas stream (re-entrainment). A series of CE and DE sections is generally necessary to achieve overall particulate collection requirements.

View Web PageDesign for Constructability

Since construction costs for some projects can exceed 50% of a total project, the cost of labor presents both the greatest opportunity and greatest risk for almost any project. A design for constructability seeks to minimize impacts and improve productivity through the elimination of rework and/or corrective action, improve material deliveries, and incorporate some type of modularization.

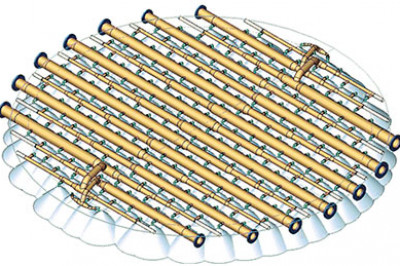

View Web PageUpgrades to Wet FGD Absorber Spray Headers

Spray header support systems are another area for potential upgrades. Older generation spray header designs used a support system that was prone to breakage which causes the header sections to fail and fall to the bottom of the absorber.

View Web PageBoiler Operations That Affect Efficiency (Part 1)

Fuel is a major cost in boiler operation. It is therefore important to minimize fuel consumption and maximize steam production. Although a boiler’s efficiency is primarily a result of its design, the operator can maintain or significantly improve efficiency by controlling losses to the stack and losses to the ash pit.

View Web PageA Numerical Modeling Example – Sorbent Injection Systems

To minimize the amount of sorbent used, it must be injected into the flue with a properly engineered lance that effectively disperses it into the gas, and the flow conditions in the flue must be sufficient for the particles to stay suspended for the required residence time to complete the desired absorption.

View Web PageEngineered Approaches in Construction, and Construction Methods

Modern construction methods include modularized components that are erected on short timetables. To reduce construction and shipping costs, leaner designs of support steel components have become the norm. As a result, the calculation of imposed erection loads has become even more critical.

View Web PageThe Importance of Boiler Water and Steam Chemistry

To maintain boiler integrity and performance and to provide steam of suitable turbine or process purity, boiler feedwater must be purified and chemically conditioned. The amount and nature of feedwater impurities that can be accommodated depend on boiler operating pressure, boiler design, steam purity requirements, type of boiler water internal treatment, blowdown rate, and whether the feedwater is used for steam attemperation.

View Web Page15 Power Plant Safety Tips

B&W values the health and safety of each employee and will never be satisfied until the workplace is free of accidents and injuries. Our focus on safety extends to our customers, contractors, suppliers, and all those who we interact with, whether on a job site, in a manufacturing facility, or even in an office setting.

View Web PageConstruction Project Controls Primer

Cost management software is used to integrate cost collection, time charging, expense reporting, work breakdown structure, procurement management, material receipt, accounts receivable, accounts payable, revenue recognition, and standard and custom report generation.

A Numerical Modeling Example – Kraft Recovery Boilers

Good air jet penetration and effective mixing of secondary and tertiary air are desirable for complete combustion and reduced emissions of carbon monoxide (CO) and hydrogen sulfide. Distribution of air to three or more air injection levels produces fuel-rich conditions in the lower furnace that are desirable for smelt reduction and reduced NOx emissions.

View Web Page