From The Leader in Clean Power Production Technologies

Millmerran Power Station Units 1 and 2

Success Story

Millmerran Power Partners

Millmerran, Queensland, Australia

Plant Owner

Millmerran Power Partners

Plant Name

Millmerran Power Station

Units 1 and 2

Project Developer

InterGen

EPC Contractor

Bechtel

Location

Millmerran, Queensland, Australia

Contract Order: 1999

Commercial Operation: 2002

B&W Scope

- Two supercritical coal-fired boilers and related equipment

- Startup and commissioning advisory services

Boiler Specifications

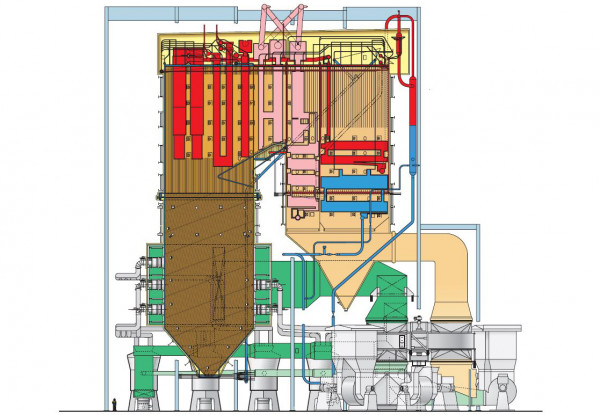

- Boiler type: Pulverized coal-fired Spiral Wound Universal Pressure (SWUP™)-type supercritical boiler

- Design fuel: Low sulfur, bituminous coal (high ash)

- Capacity: 2 X 420 MW net

- Steam flow: 2,812,000 lb/h (354 kg/s)

- Superheater outlet pressure: 3596 psig (24.8 MPa)

- SH/RH outlet temperature: 1054/1105 F (568/596 C)

Other Equipment Supplied by B&W

- B&W Roll Wheel® pulverizers, Series 98

- DRB-XCL® low NOx burners

- Diamond Power sootblower boiler cleaning system by B&W

Project Facts

- Supercritical cycle uses less coal and reduces carbon dioxide emissions when compared to a conventional coal-fired power station.

- Plant uses low sulfur coal mined from the adjacent Commodore coal deposit.

- Power station uses only 10% of the water typically required by a generating plant of this size.

- Electricity produced is pooled in Australia’s national grid to meet increased energy demand.