From The Leader in Clean Power Production Technologies

Water-Cooled Inconel® Panels in Furnace – Bolton, England

SUEZ Recycling and Recovery UK Ltd

Client: SUEZ Recycling and Recovery UK Ltd

Year: 2022

Milestones

- Contract: 06-04-2021

- Production start: 16-05-2022

- Installation completion: 18-11-2022

- Pressure test: 28-10-2022

Data

- Fuel: Waste

- Design temperature: 275 °C

- Design pressure: 59 bar(g)

Project Description

In 2021, Babcock & Wilcox Renewable Service (B&W) won the order from SUEZ Recycling and Recovery UK for engineering, manufacturing, delivery and installation of new Inconel®-cladded furnace walls for the Greater Manchester Combined Authority (GMCA)-owned Thermal Recovery Facility at Raikes Lane, Bolton, England.

High combustion temperatures were causing extensive wear on the existing refractory lining and substantial slag accumulation on the furnace walls. The consequence was a negative impact on the combustion process and high maintenance costs.

The new water-cooled side walls are integrated with the furnace and connected to the boiler drum as a natural circulating unit. This allows the absorbed heat to be added directly to the steam production.

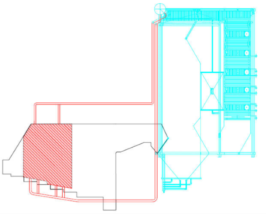

The scope included 2 x 40 m2 Inconel-cladded panel walls.

The walls were delivered in large pieces secure straightness of the panels and minimize construction time.

Inconel welding in workshop

Inconel cladding was welded in one layer using cold metal transfer (CMT). The welding was performed with vertical drops using an oscillating welding machine. Minor corrections to the machine-welded Inconel was performed by TIG welding. Inconel filler material was alloy 625 (NiCr22Mo9Nb) with Fe content below 1%.

Inconel welding on site

Two layers of Inconel cladding were manually welded to construction joints. Welding was performed with vertical drops using an oscillating welding gun. The boiler was cooled through natural water circulation during the welding.

Project scope

- CFD modelling

- Dismantling of existing furnace walls

- Inconel-cladded boiler walls

- Boiler drum and piping work to and from the panel walls

- Installation of the delivered scope of supply

- Inconel welding on site

- Refractory

- Insulation and cladding

- Transport

- Third party approval

- Pressure testing

- Documentation

Panel wall scope shown in red