From The Leader in Clean Power Production Technologies

Award-Winning Renewable Energy Facility No. 1 — Florida, USA

Success Story

Background

The Palm Beach Renewable Energy Facility (PBREF) No. 1 is a refuse-derived fuel (RDF) waste-to-energy (WTE) facility designed to reduce the volume of Palm Beach (Florida) County’s wastes, generate electricity, and maximize the recovery of ferrous and nonferrous metals. The facility is owned by the Solid Waste Authority of Palm Beach County (SWA).

Babcock & Wilcox (B&W), in a joint venture with Bechtel Corporation, engineered, procured and constructed the 2000 ton/day municipal solid waste (MSW) facility that went online in 1989. It includes two 324,000 lb/h steam capacity RDF boilers, a 62 MW turbine/generator, and flue gas cleaning equipment, along with MSW processing, storage and recycling systems. B&W also provided electrical, instrumentation and controls, and commissioning and performance testing.

A B&W subsidiary was awarded the operations and management contract for the facility in 1989 for a 20-year term, which was later extended through 2018.

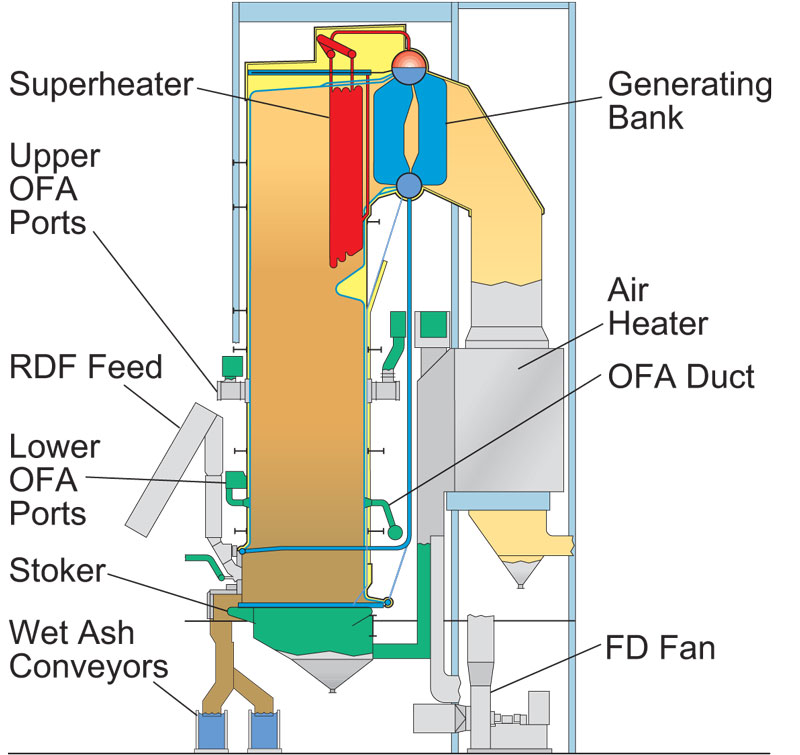

B&W also refurbished the two Stirling® power boilers at the facility by designing, supplying and fabricating critical boiler components including furnaces, superheaters, generating bank, economizer, air heater, combustion systems and steam drum internals.

The furnace and combustion system of PBREF No. 1 incorporates a straight-walled furnace design with state-of-the-art PrecisionJet® overfire air system. The plant also features state-of-the-art emissions control equipment including dry scrubbers for acid gas control, fabric filters for particulate control, selective non-catalytic reduction (SNCR) system for nitrogen oxides (NOx) control, and activated carbon injection for mercury control. This equipment makes PBREF No. 1 one of the cleanest WTE facilities in the United States.

Process description

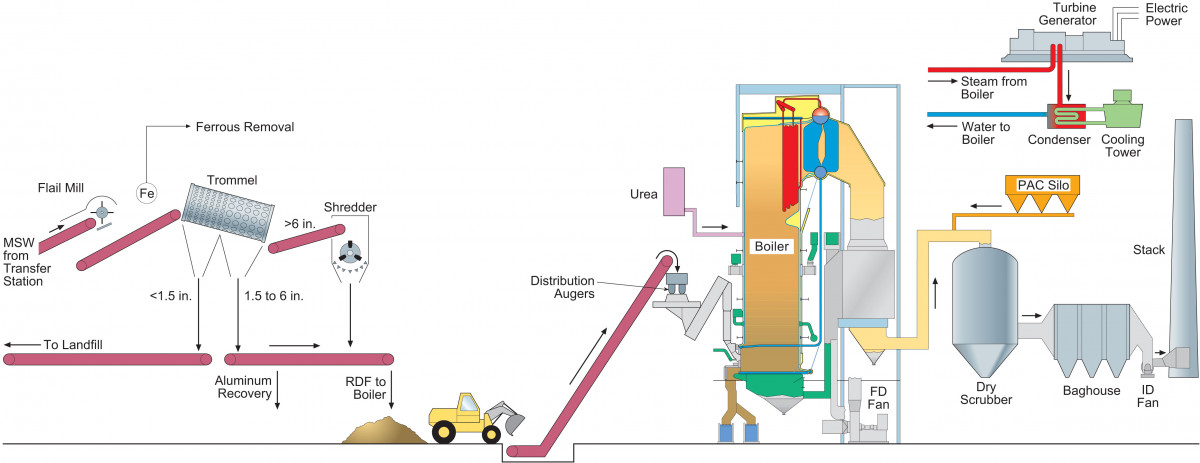

Municipal solid waste, collected from homes and businesses in Palm Beach County, is delivered to transfer stations, then transported to the resource recovery facility. MSW is delivered inside a large building where hazardous and nonprocessible materials are removed. The remaining waste is loaded onto conveyors beginning the process of conversion into a usable fuel.

The processible waste first enters a flail mill for initial size reduction. Ferrous metals are removed by an overhead magnet. The material is then separated into three distinct streams: small, low-Btu material that is hauled to landfill; medium-sized, high-Btu material; and oversized, high-Btu material that is further shredded before joining the medium-sized material for use as the RDF fuel. Aluminum and other nonferrous metals are collected by eddy current separators for recycling.

The RDF is combusted in a furnace to create steam, which is used to generate up to 62 megawatts of electricity that is sold to Florida Power & Light. As a final recycling and waste reduction effort, both ferrous and nonferrous metals are extracted from the ash after combustion.

Facility highlights and facts

- The original design and construction project was completed two months ahead of schedule and within budget.

- PBREF No. 1 was the largest refuse-derived fuel WTE facility of its kind when commercial operations began in 1989.

- The facility annually processes 795,000 tons of municipal solid waste, providing renewable energy for approximately 30,000 homes.

- PBREF No. 1 recycles both ferrous and nonferrous metals while reducing the volume of disposed waste at SWA’s landfill by more than 85%.

- For every ton of MSW processed at PBREF No. 1, one barrel of oil or one-quarter ton of coal is saved, and one ton of greenhouse gas emissions are avoided.

For the 20-year contract period ending September 2009, B&W’s subsidiary achieved the following performance:

- Processed nearly 16 million tons of municipal solid waste, nearly 3.7 million tons or 30% above its waste processing commitment.

- Produced nearly 6.9 billion net kilowatts of electricity, more than 1 billion kilowatts or 17% above its electric output commitment.

- Recovered more than 664,000 tons of ferrous metals, more than 94,000 tons or 17% above its recovered ferrous guarantee.

- Recovered nearly 63,000 tons of nonferrous metals from landfill disposal.

Award-Winning

PBREF No. 1 was awarded the American Society of Mechanical Engineers (ASME) 2009 Large Waste-to-Energy Facility Recognition Award for outstanding performance among facilities in North America. The facility also received the 2009 Solid Waste Association of North America (SWANA) Silver Excellence Award in the Waste-to-Energy facility category.