The B&W Learning Center

Leading the world in clean power production technology

Ash Handling Terminology

Ash Handling Terminology and Primer

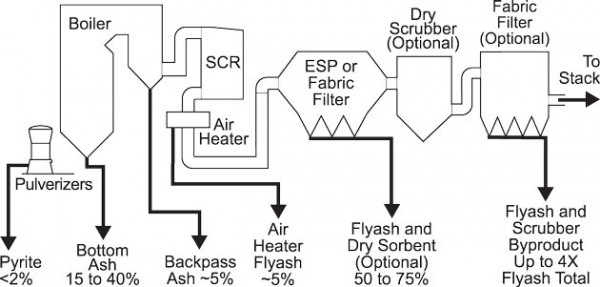

The ash handling systems of a steam generating plant collect the ash and residue from select points along the boiler flue gas stream (see illustration below), transport it to storage bins or silos, and prepare the ash for transport or disposal. Because ash characteristics are very different from the front of the boiler to the environmental equipment, the collection, transport and storage systems are usually separate for the furnace and collection points downstream.

In a coal-fired boiler, the general categories of ash are:

- Bottom ash – the material that collects at the bottom of the furnace, possibly a heavy slag.

- Mill rejects – the heavy pieces of stone, slate and iron pyrite that are discharged from the coal pulverizer.

- Economizer ash or popcorn ash – the coarse and comparatively dense particles that drop out of the flue gas when the gas changes direction abruptly, such as in the back pass and air heater ducts.

- Fly ash – the fine ash particles that are collected in the particulate control equipment.

- Scrubber byproduct – reacted lime discharged from desulfurization devices.

Ash handling terminology

- Slag – Characteristic ash removed from furnace walls

- Bottom ash – Ash removed from the bottom of the furnace

- Clinker – Large piece of bottom ash that must be broken up before transport

- Fly ash – Ash carried by the flue gas into the backpass region and beyond

- Popcorn ash – Characteristic ash collected in economizer and air heater hoppers

- Dust – Fine ash particulate, typically 50 to 75% of all ash from boiler

- Hydro ejector – Venturi device that pulls bottom ash into hydraulic transport system

- Hydrobin® – B&W trade name for dewatering bin for removing water from bottom ash

- Hydrovactor – Venturi device that provides vacuum source for pneumatic transport

- Airlock valve – Two chamber device for feeding ash into higher pressure transport line

- Materials handling valve – Valve that admits flyash and air flow into vacuum transport line

- Collector – Ash/air separator and transfer tank from vacuum system to silo

- Transporter – Flyash collection and aeration vessel for dense phase pneumatic transport

- Vacuum/pressure transfer station – Collection and transfer vessel from vacuum line to pressurized line in combination vacuum/pressure pneumatic system

- Drag chain – Primary mover in mechanical drag conveyor system

- Flights – Attached to drag chain to push ash along stationary platform

- Unloader – Device to unload dry ash storage silo into transport vehicles

- Conditioner – Adds water to flyash during unloading to minimize airborne dust

- Pugmill – One version of combined silo unloader/conditioner

Ash handling principles and applications

Bottom ash

Bottom ash is most commonly conveyed in a hydraulic system in which the ash is entrained in a high flow, circulating water system and delivered to either an ash pond or to a remote dewatering device. Alternatively, mechanical drag systems have been used to convey bottom ash to the dewatering storage bin because they use less water and usually have a lower initial cost. Both systems are designed to handle ash dropping into the conveyance system at temperatures as high as 2400F (1316C), requiring each system to have a quenching volume of water at the initial collection point (bottom ash hopper).

A more recent development is the completely dry bottom ash conveyor system. This system operates without a quenching volume of water and delivers a dry, lower carbon content material to the discharge end of the conveyor.

Rejects from the pulverizer are typically transported via the bottom ash conveyance system.

Fly ash

Most of the ash from a pulverized coal-fired boiler is carried through the boiler and air heater by the flue gas. As much as 50 to 70% of the ash generated by combustion of pulverized coal is removed from the flue gas by a particulate control device, such as a fabric filter or ESP.

Fabric filters and ESPs have rows of collection hoppers that are emptied regularly by the fly ash transport system. Fly ash consists of fine particles with low density. These particles are rarely transported in a water slurry because they cannot be easily separated from the water at the end of the transport process. For this reason, fly ash is almost always transported pneumatically. Pneumatic transport systems generally fall into four general types:

- vacuum systems,

- pressure systems,

- combination vacuum/pressure systems, or

- dense phase systems. Once economizer ash is removed from the high temperature gas stream, it can be combined with the pneumatic fly ash transport system.