Chemical Process Recovery (PR) Boilers

B&W's single-drum recovery boiler, now the standard in the pulp and paper industry, provides high availability with safe operation and low maintenance. We have been at the forefront of technologies which improve boiler and cycle efficiency, such as firing higher solids concentration liquors, using low pressure steam to heat combustion air, and feedwater heating.

Existing units can take advantage of these advanced designs and features through our range of pulp mill recovery and power boiler upgrades.

Benefits of our PR boiler design includes:

- Increased efficiency

- High availability

- Improved safety

- Low emissions (CO, NOx, SO2 and VOC particulate)

- High solids firing for optimized thermal efficiency

- Advanced steam drum internals and riser/supply systems for circulation safety margin

- Reduced construction costs and greater schedule certainty with modularized design

- Overall lower boiler lifecycle cost

Our design features include:

- Superheater, generator and economizer assemblies that are structurally stable yet minimize the use of restraints that can serve as locations for deposit accumulation and fouling

- Single- and dual-sloped floors with varying elevations of smelt spouts to meet customer requirements for frozen smelt coverage of the lower furnace

- Customized air and liquor delivery systems that are computer modeled for optimum lower furnace combustion, reduced emissions and long term cleanability

PR Boiler Specifications

Design features

A chemical and heat recovery boiler for the pulp and paper industry; concentrated black liquor and combustion air are introduced into the furnace where heat is recovered as steam for electricity generation and process heating, and the inorganic portion of the black liquor is recovered as sodium compounds.

Liquor processing capacity

To 10,000,000 lb/day (4500 t/day) dry solids

Steam pressure

To 1850 psi (12.6 MPa) design

Steam temperature

To 950F (510C)

Fuel

Pulp mill liquor

Auxiliary fuels

Natural gas and/or oil

Upgrade options to both B&W and non-B&W recovery boilers include:

- Capacity increases

- Superheater upgrades to maintain steam temperature

- Economizer replacements to improve boiler efficiency

- QuantumAir™ system upgrades for lower emissions and improved cleanability

- LM2100™ auxiliary burner retrofits

- Low odor conversions

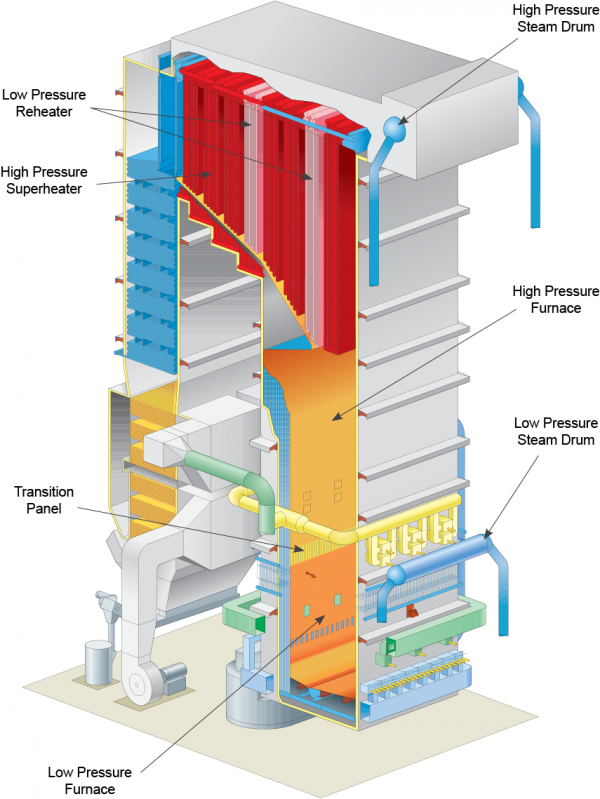

Dual Pressure Reheat Recovery Boiler

B&W has been a leading supplier of high pressure reheat boilers for electric power utilities since the 1950s. The reheat cycle greatly improves thermal efficiency for power generation.

This same technology is now available to pulp mills with our dual pressure furnace design for recovery boilers. The dual pressure furnace enables the upper furnace to operate at the high pressure and temperature needed for a reheat cycle, while the lower furnace operates at low pressures. This design eliminates the need for the exotic metals that are required to withstand a corrosive operating environment in the lower furnace.

The introduction of reheat to a pulp mill steam cycle can greatly increase the power generation Efficiency and can be applied to both recovery boilers and power boilers.

Features

- Dual pressure configuration can be part of a greenfield design or can be incorporated into an existing mill

- Patented design enables lower furnace to operate at low pressure, eliminating the need for the exotic metals and expensive alloy tubing that are required to withstand a corrosive operating environment

- Upper furnace operates at higher temperature and pressure, boosting cycle efficiency and providing optimum conditions for reheat steam production

Benefits

- Generates more power from improved steam cycle efficiency

- Uses existing fuel supply

- Takes advantage of existing plant infrastructure

- Can be operated by existing powerhouse personnel

- Lower emissions due to higher efficiency and reduced fossil fuel consumption

- Reduces carbon footprint of the mill

- Excess power can be sold to the grid as renewable power with possible carbon dioxide (CO2) Cap-and-Trade credits

- Fast return on investment