Overview

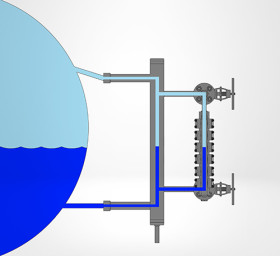

A Visual Gauge, also commonly referred to as a sight glass or boiler level gauge, is the only technology available to provide “Direct” indication of steam drum water level, thus satisfying the ASME Boiler and Pressure Vessel Code requirements. We provide a range of visual gauges and replacement parts for a variety of applications.

A Visual Gauge, also commonly referred to as a sight glass or boiler level gauge, is the only technology available to provide “Direct” indication of steam drum water level, thus satisfying the ASME Boiler and Pressure Vessel Code requirements. We provide a range of visual gauges and replacement parts for a variety of applications.

We also provide a complete line of electronic level indicators and magnetic level indicators.

Did You Know?

The ASME Boiler and Pressure Code (Section 1 Para. PG-60.1.1) states: “Boilers having a maximum allowable working pressure of 400 psi (27 bar) or less shall have at least one gage glass in service at all times. Boilers having a maximum allowable working pressure exceeding 400 psi (27 bar) shall have two gage glasses.

Instead of one of the two required gage glasses, two independent remote water level indicators (two discrete systems that continuously measure, transmit and display water level) may be provided and the required gage glass may be shut off, but shall be maintained in serviceable condition.”

TYPICAL APPLICATIONS FOR FPS® AQUARIAN PRODUCTS

- Power Boiler Steam Drum Visual Level Gauge

- Power Boiler Steam Drum Electronic Level Gauge

- Steam Drum Level Gauges for Hazardous Locations

- Feedwater Heater Electronic Level Switches

- Turbine Water Induction Protection (TWIP)

- Combined Cycle Power Plant Visual Level Gauges for HRSG Applications

- Hot well alarms

- Blow-down flash tank alarm

- Condensate Detection in High Temperature Air Systems

- Generator Coolant Liquid Level