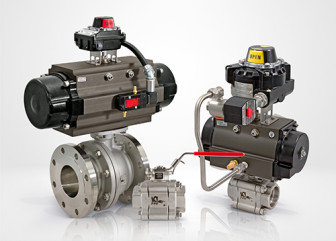

FPS® 9650 Valves

We are leaders in reliable, cost-effective, high-performance safety shut-off valve technology. Our automatic and manual shut-off valves are installed around the world in pulp and paper, petrochemical and power generation applications. FPS® valves provide low maintenance, leak proof and fail-safe operation.

The FPS 9650 Valve Series was developed to meet our ongoing requirement for high-performance safety shut-off ball valves for burner and ignitor systems. When developing the valve line, our main criteria was to create a superior quality valve package that would exceed the requirements of CSA and FM valve performance standards. FPS 9650 valves are available in both manual and automatic construction in a Series 88 and Series 90D valve body.

Approvals

FPS 9650 Valves are approved to the industry’s top standards including:

- API 607 6th Edition Fire Safe

- Factory Mutual (FM) Class 7400 for Oil and Gas

- CSA 3.16/CGA Interim Requirement No. 60 Lever Operated Shut-off Valves

- CSA 6.5/ANSI Z21.21 Automatic Valves for Gas Appliances

- CRN Registration in all required Canadian Provinces

- Meets all ASME requirements

- Functional Safety Certified to a Safety Integrity Level of SIL3

FPS 9650 Valves - Design and Specifications

- Suitable for use with gas, oil, air, water, steam and hydrogen service

- Bi-directional seal with PTFE or RTFE soft seats

- CF8M or WCB body material (CF8M = standard supply)

- Standard (70-120 psig) and low pressure (50-70 psig) actuator options available

- Ambient design temperature range of -40 to 50 °C

- 3-Stage triple redundant stem seal provides maintenance free operation

- Leak watch window in valve body allows the user to check the steam seal for potential leakage.

Our advantages include very short delivery times, prompt quote turnaround with technical support, and the ability to meet end user specifications with an array of approvals. These features paired with a reliable, proven and robust valve design has advanced FPS as a leader in fail-safe valve offerings – worldwide.

Consult with us on your specific design requirements as alternative assemblies may be available.