Overview

Magnetic Level Indicators for steam and process applications are designed for high performance and reliability while providing a totally leak-proof, non-invasive method to measure level. This technology has particular relevance when using with dangerous or flammable liquids.

We also provide a complete line of electronic level indicators and visual level gauges (or boiler sight glass).

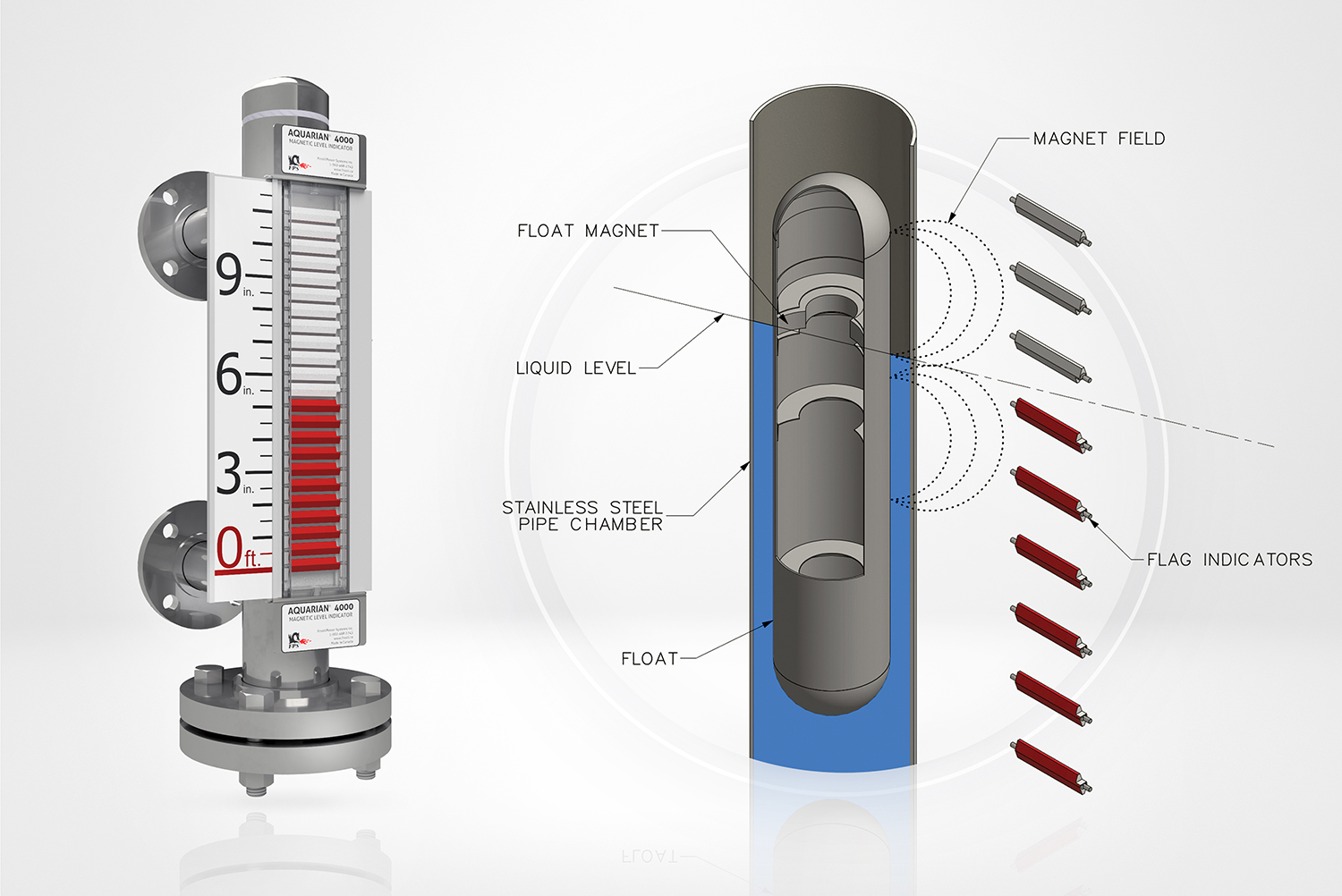

The FPS®Aquarian® 4000 Magnetic Level Indicator (MLI) is a new approach to level measurement. The Magnetic Level Indicator provides a totally leak-proof, non-invasive method to measure levels. This is especially advantageous when process fluids are dangerous or flammable. The isolation of the indicator from the process fluid also limits the amount of regular maintenance required for the indicator. Each float is specifically designed to function in the specific gravity (SG) of the process fluid present, providing accurate level readings.

The Magnetic Level Indicator uses a non-magnetic float with an internal magnet that is coupled to the magnetic two-color indicator flags. The float is enclosed within a 316 stainless steel pipe chamber that is connected to the process vessel. The flags are held in an aluminum frame within a sealed polycarbonate extrusion. As the process fluid rises or lowers, the flags rotate to indicate the fluid level.

Features and Typical Applications

Features and Benefits

- Designed for 1350 psi (93 bar) and 700F (370C)

- 5-year warranty on all parts

- 1.75-inch flag width provides 300 ft viewing distance with 140° viewing angle

- Machined flag holders provide accurate flag spacing and low flag rotation friction

- Floats constructed in 321 stainless steel or titanium, depending on application requirements

- High strength rare earth float magnet provides reliable magnetic coupling to the flags

- High contrast bi-colored indicator flags for easy visibility

- Large high contrast scale provides long distance viewing

- Fully sealed and nitrogen purged flag assembly for reliability in all environmental conditions

- Specific gravity fluids as low as 0.66

- Constructed to the ASME Boiler and Pressure Vessel Code requirements for design, materials, and construction.

Typical Applications for the Magnetic Level Indicator

- Boiler Drums

- Hot Wells

- Blowdown Tanks

- Feedwater Heaters

- Deaerators

- Propane Vessels

- Oil/Water Separators

- Chemical Tanks

- Gas Chillers

- Oil and Gas Industry

- Pulp and Paper Industry