For a net-zero future

The B&W Learning Center

Leading the world in clean power production technology

Wet cooling system design options

Choosing Between Crossflow and Counterflow Cooling Towers

A cooling tower is a heat rejection device used to transfer process waste heat to the atmosphere. It is commonly used in several plant types to cool water by evaporating a portion of fluid and removing heat, then circulating the cooled water back to the process.

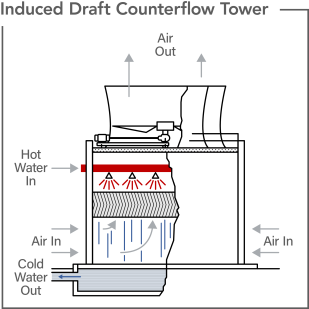

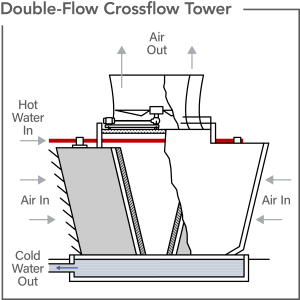

Crossflow and Counterflow cooling towers are two different types of wet cooling systems used to remove heat from industrial processes. The main difference between the two is the direction of airflow relative to the water flow: in crossflow towers, water flow is perpendicular to the air flow; in counterflow towers, water flows in a parallel, opposite direction of air flow.

The choice between the two types of cooling towers typically depends on many factors including available space, seasonal temperatures, noise limitations and other considerations.

What are the primary differences between crossflow cooling towers and counterflow cooling towers?

Counterflow cooling towers have high thermal efficiency due to the performance of their distribution system. Both splash and film fills can be parts of them, depending on the water quality.

Counterflow cooling towers have high thermal efficiency due to the performance of their distribution system. Both splash and film fills can be parts of them, depending on the water quality.

In counterflow towers, louvers at air entry are not required, so the total pressure drop is reduced; pumping head is low, since the air flowing area from the bottom portion is small; and operating costs are low. In crossflow towers, louvers are a must, leading to a pressure drop increase, and the pumping head required is high, since the air flowing area is wide.

Counterflow cooling towers are known for their more efficient distribution system. In these towers, water is evenly distributed over the fill material, typically through a system of pressurized spray nozzles or distribution trays. This even distribution ensures that water is spread uniformly across the surface of the fill material, facilitating effective heat exchange between the water and the air.

In contrast, crossflow cooling towers typically have a less efficient distribution system. Water is usually distributed at the top of the tower and allowed to flow down over the fill material in a more natural, gravity- driven manner. This method can result in uneven distribution of water over the fill material, leading to variations in cooling efficiency.

driven manner. This method can result in uneven distribution of water over the fill material, leading to variations in cooling efficiency.

To compensate for the less efficient distribution system in crossflow cooling towers, splash fills are commonly used. Splash fills are designed to enhance water distribution and increase the contact surface area between water and air. These fills consist of a series of corrugated or textured sheets that promote the breakup of falling water into smaller droplets. As the water droplets fall and collide with the fill material, they create additional surface area for heat exchange. By using splash fills in crossflow cooling towers, cooling efficiency can be improved.

How is maintenance different for crossflow and counterflow cooling towers?

In crossflow cooling towers material handling and maintenance on the tower deck may be difficult due to limited space availability. The water distribution tray is fixed and covers a large part of the fan deck area opposite the fan stack.

Maintenance in counterflow cooling towers is generally easier compared to crossflow cooling towers due to several factors: better accessibility, easier cleaning, better distribution system and easier access to some key components. The fill material (usually film fill) is typically located near the top of the tower, making it easily accessible for inspection and maintenance. The dispersion and distribution systems are more accessible and adjustable.

Crossflow towers may have structural elements or obstructions in the path of maintenance personnel, making it more challenging to navigate and perform maintenance tasks.

Counterflow towers tend to have a more open design, providing easier access. These factors contribute to reduced downtime, lower maintenance costs, and improved long-term performance.

What other factors are considered?

In crossflow cooling towers, the noise emissions are typically higher. There is also wide exposure to sunlight since the distribution tray is at deck level and open to the atmosphere. In counterflow cooling towers, the noise emission is comparably lower due to the narrower emissions area, and exposure to sunlight is limited since the distribution system is enclosed with the casings and deck.

Summary

Babcock & Wilcox has extensive experience in engineering, designing, and installing best-in-class SPIG® technology in both counterflow and crossflow cooling towers. Many customers prefer counterflow cooling towers based on efficiency, maintenance and emissions project goals. We leverage our more than 85 years’ experience from a wide reference list of SPIG Cooling Towers supplied all over the world to help customers identify, customize and integrate the best technology for their footprint and application.