Success Stories

From The Leader in Clean Power Production Technologies

IVM Eeklo

WTE Boiler and Furnace Upgrades - Eeklo, Belgium

Client: Engie Fabricom, Industry South

Client: Engie Fabricom, Industry South

Year: 2020

Milestones

- Contract: 15-03-2018

- Delivery on site: 15-04-2019

- Hand over: 28-08-2020

Data

- Fuel: Waste

- Steam temperature: 415 oC

- Steam pressure: 55 bar(g)

Project description

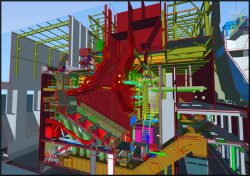

Babcock & Wilcox Renewable Service won the order of an extensive upgrade project for two identical waste-to-energy lines in Eeklo, Belgium.

The scope included engineering, manufacturing, delivery, construction advisory services, commissioning, testing, operator training, and project management for new feeding systems, grates, riddlings and slag handling systems, water-cooled furnaces, combustion air system, support burners and hydraulic system.

Computational fluid dynamic (CFD) models were utilized to determine new furnace geometry, secondary air nozzle and burner locations, and to predict the temperature distribution.

Scope of delivery

Feeding system

Waste feeding hopper, hydraulically operated feed damper, water-cooled chute, feeding pusher, and casing around the grate and boiler.

Combustion grate

Air-cooled hydraulically driven DynaGrate® combustion grate, 2.8 m wide and 9.9 m long

Siftings and slag system

Four air zones and sifting hoppers under the grate with a common submerged conveyor underneath the set of sifting hoppers and slag chute. The submerged conveyor, which is based on wet operation, feeds the siftings into an open container in an outside container hall.

Start-up burners

Two 12.5 MW start-up/support burners for natural gas including local instruments, valves and PLC.

Combustion air system

Basic design of primary, secondary and cooling air systems.

Water-cooled furnace

Water-cooled furnace constructed of panel walls and wear zones. Furnace walls use Inconel® cladding with the exception of front and rear roofs. Six riser pipes from new furnace connected to existing steam drum. Supply pipes for new furnace connected to existing downcomer pipes.

Furnace walls were pressure tested and Inconel cladded in workshop before delivery to site.

Galleries, platforms and support steel

Basic design of galleries, platforms and support structural steel for B&W Renewable supplied equipment.

Valves

Complete valve package.

Hydraulic system

Complete hydraulic system for grate, feeding pusher and damper in feeding chute including local instruments, valves and pipes and spill protection bin.

Results

- An extended asset life is anticipated from these results:

- Safer and easier daily maintenance

- More stable combustion process

- More stable steam production

- Up to 12.5% higher energy recovery

- Greater electricity production

- Better permit compliance

- 35% less fly ash

- Longer run time between outages