Success Stories

From The Leader in Clean Power Production Technologies

From Black Liquor to Sludge Case Study

From Black Liquor to Sludge: Converting a Recovery Boiler to a Bubbling Fluid Bed

Boiler conversion extends asset life to meet plant’s renewable energy needs.

Background

Conversion of the plant’s unneeded recovery boiler as a bubbling fluidized-bed (BFB) power boiler provides an economic and environmentally sound solution to:

- Burn paper mill sludge, wood waste and tires to displace other more expensive fossil fuels

- Enable existing boiler assets to be fully utilized, such as the upper furnace, superheater, boiler bank and precipitator

- Reduce landfill costs by utilizing mill sludge as a fuel source

Solution: Reduce Capital Costs of a New Power Boiler Island

Babcock & Wilcox (B&W) has extensive experience with boiler conversions and modifications, including extensive refurbishments of older recovery boilers to BFB conversion while reusing existing buildings and ancillary equipment.

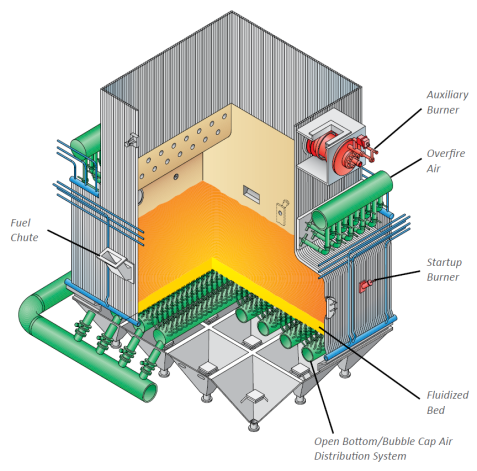

B&W’s renewable solution – an open-bottom, BFB unit – addresses the project’s special concerns and is helping the customer achieve its goals of increased steam flow, fuel conversions and reduced emissions.

Unique Project Features and Challenges

- Utilizing bottom supported BFB hoppers reduced boiler weight to top steel through use of B&W’s innovative bed seal design

- Auxiliary equipment and construction activities required insightful planning and procedures to accommodate demolition, installation of new equipment and start-up

Successful Outcomes

B&W’s expert design was successful at converting the customer’s boiler to a BFB with an increased steam flow of more than 65 % and meeting emissions requirements while utilizing waste and opportunity fuels available at lower costs than traditional fossil fuels at the plant.

This renewable project resulted in converting a once stranded asset into a valued asset at lower capital costs. The plant continues to serve as a model conversion facility.

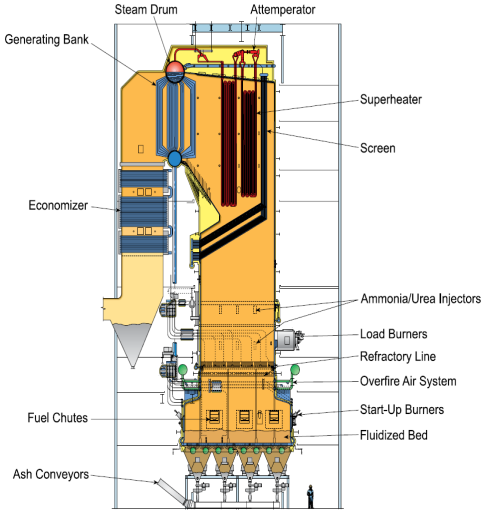

Sideview of Recovery Boiler Converted to B&W’s Open-bottom BFB Design

B&W’s open-bottom BFB furnace design provides complete debris removal with lower capital costs and maintenance expenses.