Success Stories

From The Leader in Clean Power Production Technologies

Likeng II: Guangzhou, China Case Study

Likeng II: Guangzhou, China

Babcock & Wilcox Vølund’s license partner Grantop (Guangzhou Environment Protection Investment Co. Ltd.) has completed the Likeng II waste-to-energy plant in Guangzhou, China. The plant is one of the largest Chinese waste-to-energy plants and it is specifically designed for Chinese waste. This includes the waste characteristics with high moisture and low calorific value.

The Likeng II plant has 3 lines of 750 tonnes waste capacity per day each, based on B&W Vølund engineering design and key components.

Scope of Supply

Babcock and Wilcox Vølund has supplied:

- Basic design of boiler including technical assistance for construction and commissioning. Furthermore, a review of boiler detail design a review of boiler detail design and functional description for DCS.

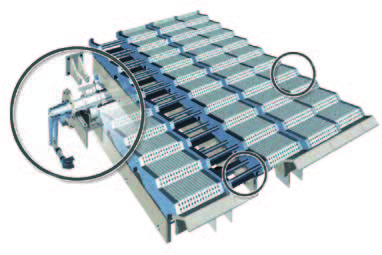

- Air-cooled Vølund grate.

- Waste charging system with a feeding damper.

- Feeding chute and feeding pusher.

- Slag pusher.

- Construction and commissioning advisors.

The Vølund Grate

The Babcock & Wilcox Vølund air-cooled grate is a longitudinal beam grate– a thoroughly proven design, highly suitable for continuous high-efficiency combustion of mixed household and bulk industrial waste with minimal emission of harmful substances and maximum energy recovery.

The beam grate is of a robust design, specifically developed for heavy-duty and high-temperature operation with a high availability and operational reliability thus ensuring minimal shutdown for routine maintenance and cleaning.

- Minimum emission of harmful substances and maximum energy recovery.

- High availability and operational reliability with minimal downtime.

- Perfect air distribution and minimal power consumption.

- Combustion of all types of waste.

- High thermal efficiency.

- Handling of unsorted waste.

- Low total organic carbon in ash content.

- Possibility of biomass co-firing.

| Data Plant Design | ||

| Process Parameters | Values | Units |

| Waste Capacity | 3 x 31.3 | t/h |

| Heat Value, Lower | 6.8 | MJ/kg |

| Steam Output | 3 x 63 | t/h |

| Steam Temperature | 400 | °C |

| Steam Pressure | 40 | bar |

| Gross Electric Output | 2 x 25 | MW |

| Feed Water Temperature | 130 | °C |