Success Stories

From The Leader in Clean Power Production Technologies

Keephills Unit 3 Case Study

Spray Dryer Absorber, Pulse Jet Fabric Filter and Mercury Control Systems

TransAlta and Capital Power

Wabamun, Alberta, Canada

Contract Order: 2007

Commercial Operation: 2011

Overview

Babcock & Wilcox spray dryer absorber (SDA) systems feature a combination of design components to provide a level of reliability and sulfur dioxide (SO2) removal efficiencies that are among the highest in the industry.

B&W is the exclusive North American licensee of GEA Process Engineering A/S, Denmark, for the GEA Niro SDA process. The GEA Niro SDA is globally recognized by the power generation industry as the dry scrubber technology of choice.

Features of the system include a unique flue gas dispersion system for optimal gas and reagent mixing, a low maintenance rotary atomizer with a slurry capacity that is among the highest in the industry, large SDA chambers, and a complete reagent recycle system. Benefits include high SO2 removal efficiency, low capital cost, high system availability, and low operation and maintenance costs.

Boiler/Plant Information:

Unit 3:

495 MW

Boiler type:

Hitachi supercritical pulverized coal with natural gas for startup

Design fuel:

Western subbituminous

Project Summary

B&W's project scope includes an SDA system to limit SO2 emissions, consisting of 2 x 50% SDA vessels and reagent preparation system (for lime and recycle ash), a pulse jet fabric filter (PJFF), and a sorbent injection system using powdered activated carbon (PAC) to limit mercury emissions.

B&W Scope

- Two SDA modules, size 10000 (16 meter)

- Two Niro F800 rotary atomizers

- SDA inlet and interconnecting flues

- Lime preparation system with paste slakers

- Recycle solids preparation system

- Eight compartment plenum style PJFF with integral bypass

- PPS/P84 filter bags

- Pulse air cleaning system

- Sorbent injection system for mercury control using PAC reagent

Results

- Met all performance and reliability run guarantees

- Project was structured using a variable price/fixed price arrangement and was executed on budget and below the original price estimate

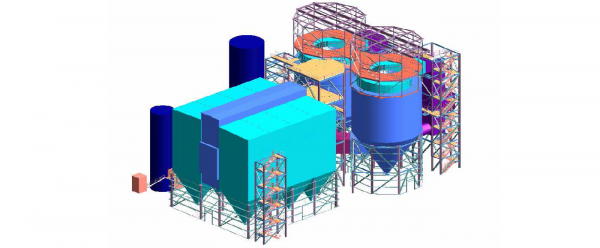

3D Projection of Keephills Unit 3 SDAs and Pulse Jet Fabric Filter