Induction Heat Tube Extraction (IHTE)

Over time, fireside tube wastage typically results in the need to replace generating bank tubes, including the stub ends rolled into the tube seats of the steam and mud drums. B&W offers a proven solution that minimizes costs and boiler downtime and preserves the boiler drum shell.

Our patented induction heat tube extraction technology, formerly known as Tubesolve™, has been used to remove more than 90,000 tube stubs in various industries. These include power generation, pulp and paper, waste-to-energy, oil refining, gas processing, chemical processing and institutional heating applications. It is electronically controlled for more precise, instantaneous, accurate, contact-free results.

Our process:

- Provides for quick, efficient and safe tube stub removal

- Eliminates the need for carbon arc gouging or torch splitting

- Eliminates tube sheet damage

- Reduces tube seat cleaning requirements by at least half

Proven benefits include:

- Reduced project cost and schedule

- Improved quality

- Reduced risk exposure and enhanced safety

Induction heating permits the selective, rapid, concentrated, local heating of metal without damaging the tube seat or affecting the surrounding material grain structure.

Two methods for removal

B&W has developed two unique methods for removing tube stubs from tube sheets and drums:

- Heat and Shrink – for drums without seating grooves or too small to get inside

- Heat and Pull – for most other applications

Both methods eliminate the need for conventional carbon arc or acetylene splitting of the tube stubs as well as the potential damage to the tube seats and subsequent repair requirements.

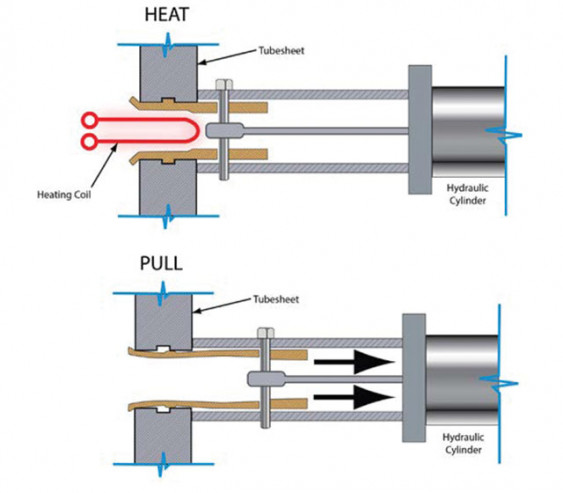

Heat and pull

The Heat and Pull method rapidly heats the tube stubs in situ to 1000C, using a specially designed induction coil. The tube stub is extracted by hydraulic jacking from outside the drum. The Heat and Pull method is particularly suited for the removal of heavily over-expanded tube stubs from headers and drums. Prior bell removal is not required, as the bell collapses and is pulled through with the stub.

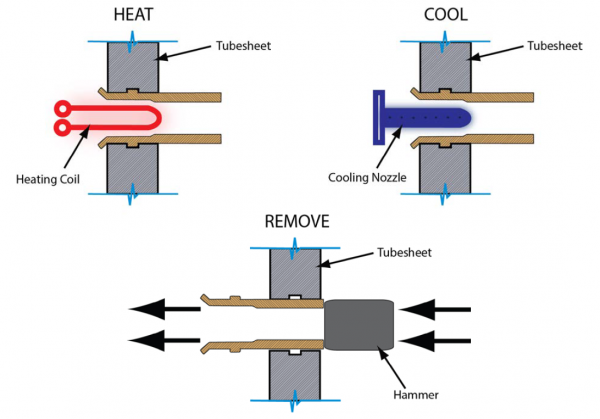

Heat and shrink

The Heat and Shrink method heats the tube stubs in situ to 1000C, using a specially designed induction coil. When cooled, such as by the application of compressed air to the tube, the tube shrinks, breaking contact with the drum and providing for ease of removal. The tube stub can then be easily driven out of the tube bore.