Boiler Parts

Babcock & Wilcox is a single-source supplier for quality, dependability and reliability when it comes to replacement parts and services. A wide range of power plant, boiler, auxiliary and environmental equipment replacement parts and services is available. Our boiler component capabilities include:

Pressure Parts

- Straight and bent boiler tubes

- Tube wall panels

- Complete package boiler retubing

- Burner, sootblower and air port openings

- Superheater and economizer sections

- Headers and steam drums

- Division walls and wing walls

- Tubes for Cyclone furnaces

- High-temperature alloy materials

Non-pressure Parts

- Coal, gas and oil burner components

- Coal pipes and valves

- Diamond Power® sootblowers

- Fossil Power System (FPS™) igniters and scanners

- Cera-VAM® ceramic products

- Liquor recovery equipment

- Bottom and fly ash equipment

- Expansion joints and dampers

- Miscellaneous boiler components

- Attemperators

- Air heaters

Upgrades & Retrofits

We have also successfully completed thousands of improvement projects to existing B&W and non-B&W utility and industrial boilers. Many of these projects required innovative design, material or product solutions that significantly enhanced equipment performance and reliability. Advanced longer-lasting materials, improved designs, and application-specific pressure part arrangements are just a few ways that installed boilers benefit from our upgrade projects.

Learn More About B&W Upgrades & Retrofits

Babcock & Wilcox® Boiler and Environmental Parts & Service

Phone: +1 330 860 1460 or toll free within

North America 1 800 354 4400

After-hours 1-800-BABCOCK

Diamond Power® Boiler Cleaning Parts & Service

Phone: +1 740 687 4160 or toll free within

North America 1 800 848 5086

After-hours Emergencies 1 800 876 9762

Allen-Sherman-Hoff® Ash Handling Parts and Service

Phone: +1 740 687 4160 or toll free within

North America 1 800 848 5086

After-hours Emergencies 1 800 876 9762

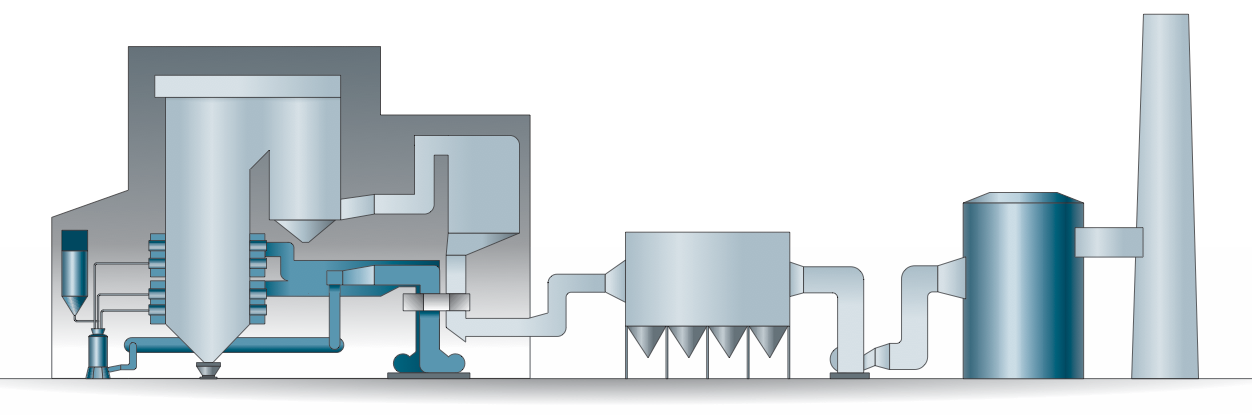

Power Plant Parts, Upgrades, Controls and Services

How do you maintain your competitive edge in today’s market? Are you operating at peak efficiency and maximizing the returns on your assets? Are you partnering with a proven service provider you can rely on to provide ongoing maintenance support, quality replacement parts and new technologies when needed to meet the latest environmental regulations?

These are some of the reasons to choose Babcock & Wilcox as your one-stop aftermarket supplier for your entire plant. Use this quick guide to learn more about the vital parts of our Power Plant Parts, Upgrades, Controls and Services. Hover or tap on a dot to learn more.

Combustion Systems

- Pulverizers

- Low NOx burners

- Igniters and scanners

- Overfire air systems

- Cyclone furnaces

Combustion Systems

- Pulverizers

- Low NOx burners

- Igniters and scanners

- Overfire air systems

- Cyclone furnaces

Boiler

- Pressure parts

- Non-pressure parts

- Diamond Power® sootblowers

- Air heaters

- Fans

Controls and Diagnostic Systems

- Advanced performance technologies

- Sootblowing controls and intelligent software

- Precipitator controls and software

- Boiler control and monitoring systems

Post-Combustion NOx Control

- Selective catalytic reduction

- Selective non-catalytic reduction

Ash and Material Handling

- Allen-Sherman-Hoff® bottom ash systems

- Allen-Sherman-Hoff® fly ash systems

Ash and Material Handling

- Allen-Sherman-Hoff® bottom ash systems

- Allen-Sherman-Hoff® fly ash systems

Particulate Control

- Electrostatic precipitators (ESP)

- Fabric filter baghouses

- Dust collectors

Mercury, Acid Gas and HAP Control

- Wet scrubbers

- Dry scrubbers

- Dry sorbent injection

- Activated carbon injection

Tube Bending Capabilities

Babcock & Wilcox is committed to servicing your existing fleet, with extensive experience in delivering tubes for utility, refinery, petrochemical, pulp & paper, processing, and other industries. Customers around the globe know they can count on us for on-time delivery of high-quality components.

Strategically located for fast response, our service centers offer both hot and cold tube bending capabilities to best meet your requirements for material, sizing and application.

We supply carbon, stainless or alloy steel tubing for superheater loops, partial superheater tubes, and sections for superheaters, economizers, generating banks, and supply and riser tubes.

Our premiere hot-tube bending is preferred for applications requiring tight radius bends, as it limits wall thinning and maintains cross-section integrity.

Boiler Tubing Stocked Inventory

We maintain an expansive inventory of tubes in varying sizes and grades to meet emergency or scheduled outage delivery requirements. The following is a partial list of some of the more commonly requested tubes by outer diameter, minimum wall and grade specifications. We stock additional sizes and grades not listed, so please contact us for availability or a quote.

| O.D. | M.W. | Grade |

| 0.750 | 0.180 | SA192 |

| 0.875 | 0.148 | SA213T2 |

| 1.000 | 0.165 | SA213T2 |

| 1.031 | 0.180 | SA210A1 |

| 1.250 | 0.203 | SA213T2 |

| 1.250 | 0.220 | SA213T2 |

| 1.375 | 0.220 | SA213T2 |

| 1.375 | 0.240 | SA213T2 SID |

| 1.375 | 0.250 | SA213T2 SID |

| 1.750 | 0.125 | SA192 |

| 1.750 | 0.250 | SA192 |

| 1.750 | 0.180 | SA210A1 |

| 1.750 | 0.203 | SA213T22 |

| 1.750 | 0.220 | SA213T22 |

| 1.750 | 0.260 | SA213T22 |

| 1.750 | 0.280 | SA213T22 |

| 1.750 | 0.320 | SA213T22 |

| 1.750 | 0.360 | SA213T22 |

| 2.000 | 0.095 | SA178A |

| 2.000 | 0.110 | SA178A |

| 2.000 | 0.135 | SA178A |

| 2.000 | 0.135 | SA210A1 |

| 2.000 | 0.150 | SA210A1 |

| 2.000 | 0.165 | SA210A1 |

| 2.000 | 0.180 | SA210A1 |

| 2.000 | 0.203 | SA210A1 |

| 2.000 | 0.220 | SA210A1 |

| 2.000 | 0.240 | SA210A1 |

| 2.000 | 0.260 | SA210A1 |

| 2.000 | 0.280 | SA210A1 |

| 2.000 | 0.300 | SA210A1 |

| 2.000 | 0.135 | SA213T22 |

| 2.000 | 0.150 | SA213T22 |

| 2.000 | 0.165 | SA213T22 |

| 2.000 | 0.180 | SA213T22 |

| 2.000 | 0.203 | SA213T22 |

| 2.000 | 0.220 | SA213T22 |

| 2.000 | 0.240 | SA213T22 |

| 2.000 | 0.260 | SA213T22 |

| 2.000 | 0.280 | SA213T22 |

| 2.000 | 0.300 | SA213T22 |

| 2.000 | 0.320 | SA213T22 |

| 2.000 | 0.340 | SA213T22 |

| 2.000 | 0.360 | SA213T22 |

| 2.000 | 0.380 | SA213T22 |

| 2.125 | 0.165 | SA213TP347H |

| 2.250 | 0.220 | SA210A1 |

| 2.250 | 0.165 | SA213T22 |

| 2.250 | 0.180 | SA213T22 |

| 2.250 | 0.203 | SA213T22 |

| 2.250 | 0.220 | SA213T22 |

| 2.250 | 0.240 | SA213T22 |

| 2.250 | 0.260 | SA213T22 |

| 2.250 | 0.165 | SA213T91 |

| 2.250 | 0.180 | SA213TP304H |

| 2.500 | 0.135 | SA178A |

| 2.500 | 0.275 | SA178C |

| 2.500 | 0.275 | SA210/304 |

| O.D. | M.W. | Grade |

| 2.500 | 0.125 | SA210A1 |

| 2.500 | 0.150 | SA210A1 |

| 2.500 | 0.165 | SA210A1 |

| 2.500 | 0.180 | SA210A1 |

| 2.500 | 0.203 | SA210A1 |

| 2.500 | 0.220 | SA210A1 |

| 2.500 | 0.240 | SA210A1 |

| 2.500 | 0.260 | SA210A1 |

| 2.500 | 0.280 | SA210A1 |

| 2.500 | 0.300 | SA210A1 |

| 2.500 | 0.260 | SA210A1 MLR |

| 2.500 | 0.257 | SA210A1*/825 |

| 2.500 | 0.270 | SA210A1MLR |

| 2.500 | 0.300 | SA210A1MLR |

| 2.500 | 0.150 | SA213T22 |

| 2.500 | 0.165 | SA213T22 |

| 2.500 | 0.180 | SA213T22 |

| 2.500 | 0.203 | SA213T22 |

| 2.500 | 0.220 | SA213T22 |

| 2.500 | 0.240 | SA213T22 |

| 2.500 | 0.260 | SA213T22 |

| 2.500 | 0.280 | SA213T22 |

| 2.500 | 0.300 | SA213T22 |

| 2.500 | 0.260 | SA213T2MLR |

| 2.500 | 0.165 | SA213T91 |

| 2.500 | 0.180 | SA213TP304H |

| 2.750 | 0.240 | SA210A1 |

| 2.750 | 0.290 | SA210A1 |

| 2.750 | 0.290 | SA210A1MLR |

| 2.750 | 0.240 | SA213T22 |

| 2.750 | 0.480 | SA213T22 |

| 2.969 | 0.165 | SA210A1 |

| 2.969 | 0.180 | SA210A1 |

| 2.969 | 0.203 | SA210A1 |

| 2.969 | 0.220 | SA210A1 |

| 2.969 | 0.240 | SA210A1 |

| 2.969 | 0.260 | SA210A1 |

| 2.969 | 0.300 | SA210A1 |

| 3.000 | 0.259 | SA210/304L |

| 3.000 | 0.180 | SA210A1 |

| 3.000 | 0.220 | SA210A1 |

| 3.000 | 0.240 | SA210A1 |

| 3.000 | 0.260 | SA210A1 |

| 3.000 | 0.300 | SA210A1 |

| 3.000 | 0.320 | SA210A1 |

| 3.000 | 0.340 | SA210A1 |

| 3.250 | 0.135 | SA210A1 |

| 3.250 | 0.180 | SA210A1 |

| 3.250 | 0.203 | SA210A1 |

| 3.250 | 0.340 | SA210A1 |

| 4.000 | 0.180 | SA210A1 |

| 4.000 | 0.203 | SA210A1 |

| 4.000 | 0.240 | SA210A1 |

| 4.000 | 0.380 | SA210A1 |

| 4.500 | 0.220 | SA210A1 |

| 5.000 | 0.135 | SA178A |

| 5.000 | 0.500 | SA210A1 |