What is Biomass Energy?

Proven Technology to Utilize Biomass as a Renewable Energy Source

Biomass is a renewable energy source consisting of living or recently living organisms. Generally, this means plants and trees in the form of industrial and agricultural scrap.

How a Biomass Combustion Energy Plant Works

Our biomass technology provides a carbon-neutral power generation option. Since biomass consists of “recently alive” material, burning biomass is CO2-neutral in the sense that it only releases the quantity of CO2 that the plant absorbed during growth.

Some biomass needs pre-treatment before the fuel is fed onto a combustion grate where it is burned. The heat from the combustion is used to fire the boiler, which in turn generates hot water or steam. The steam turns a turbine which produces electricity.

Biomass Fuel Types

In general, biomass fuels are evaluated on the basis of their physical properties (density, size distribution, humidity, foreign matter) and chemical properties (calorific value, proximate analyses, ultimate analyses, ash analyses, and ash-melting behavior).

In general, biomass fuels are evaluated on the basis of their physical properties (density, size distribution, humidity, foreign matter) and chemical properties (calorific value, proximate analyses, ultimate analyses, ash analyses, and ash-melting behavior).

Today we can recover energy from biomass in highly efficient energy plants – generating heat, process steam, electricity, syngas, and/or bio-oil. Many of our biomass energy solutions are combined heat and power (CHP).

Biomass can be derived from a variety of sources, and it’s essential to understand the properties and chemical composition of each one. Some biomass needs pre-treatment before the fuel is fed onto a combustion grate where it is burned.

Biomass Fuels Include:

- Sawdust

- Wood chips

- Bark chips

- Straw

- Waste wood

- Other opportunity fuels

Biomass Technologies & Services

B&W has been trusted suppliers of biomass combustion technologies for many years. Our extensive list of commercially demonstrated and industry-accepted products have stood the test of time in providing reliable steam generation for both process and electric power applications. While offering a highly available and readily dispatchable renewable energy source, the combustion of biomass also provides environmental benefits such as reduced emissions of nitrogen oxides (NOx), sulfur oxides (SOx), and mercury, when compared with other fossil fuels. Biomass is also a carbon dioxide (CO2)-neutral renewable energy source.

Biomass combustion:

- Pretreatment technologies

- Stokers (air spouts, screw feeder, ram feeder)

- Bubbling fluidized-bed, circulating fluidized-bed and stoker boilers

- Combustion technologies (vibrating grate, burners)

- Ash extraction

Emissions control:

- Selective catalytic reduction (SCR) systems for NOx reduction

- Electrostatic precipitator (ESP) or fabric filter for particulate control

- Flue gas desulfurization system for SO2 and acid gas control

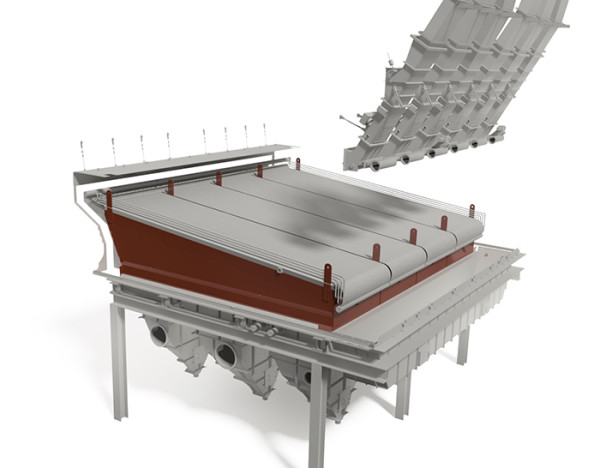

Water-Cooled Vibrating Grates for Biomass Combustion

B&W’s water-cooled vibrating grate is ideal for burning most types of biomass including wood chips, sawdust, wood pellets, bark, wheat and rice straw, rice husks and palm waste. A high preheating temperature of primary combustion air and in special cases, mounting of cast iron plates, make it possible to burn fuels with high moisture content.

Features

- Heat release rate up to 2.5 MW/m2

- Suitable for a wide range of boilers, from 10 to 250 MW (input)

- Primary air can be heated to a temperature of more than 300 °C

- Allows combustion of fuels with high moisture content.

- Grate cooling is a standard component of the boiler evaporator system.

- Air flow through the grate can be optimized and minimized as there is no need for air cooling

- High availability, low maintenance costs and a low consumption of spare parts