Success Stories

From The Leader in Clean Power Production Technologies

Diamonized® Feed Tubes Case Study

North American Pulp Mill — Diamonized® Feed Tubes

Plant Description

North America-based pulp mill equipped with Kraft recovery boiler.

Project Challenge

Premature packing wear from normal cycling caused excessive steam leaks in the sootblower feed tubes located in the boiler’s superheater. A solution was needed that would extend the life of the feed tubes and minimize maintenance.

The mill had considered two options:

- New feed tubes with hard surface coatings: Electroplated coatings provide a hard surface, but

are prone to spawling and flaking due to the difference of thermal expansion of the electroplated material and the base metal. Coating failure will cause steam leaks. - Thermal-sprayed feed tubes: Sprayed coatings, like the electroplated coatings, often fail. As the dissimilar materials are heated, thermal expansion attacks the bond causing coating failure and subsequent surface spawls, premature packing failure and steam leaks.

Solution

The customer selected Diamonized® feed tubes from Babcock & Wilcox (B&W).

Diamonized feed tubes provide a surface that is 20% harder than chrome (Rc 66 vs. Rc 52). Unlike chrome or sprayed thermal coatings, Diamonized feed tubes are manufactured using a patented process that creates an abrasion-resistant surface by hardening the metal itself. This process avoids coating or spraying material onto the base metal and, subsequently, prevents coating-related flaking and spawling. Diamonized feed tubes provide a hard surface that can help to extend time between feed tube change-outs, extend packing life and minimize the potential for packing-related steam leaks.

Results

Diamonized feed tubes, installed in April 1997, ran consistently for nearly 10 years. They were removed in February 2007 for inspection, after approximately 70,400 cycles, and were returned to service.

Throughout the life span of the Diamonized feed tubes, savings at the mill were realized in many ways:

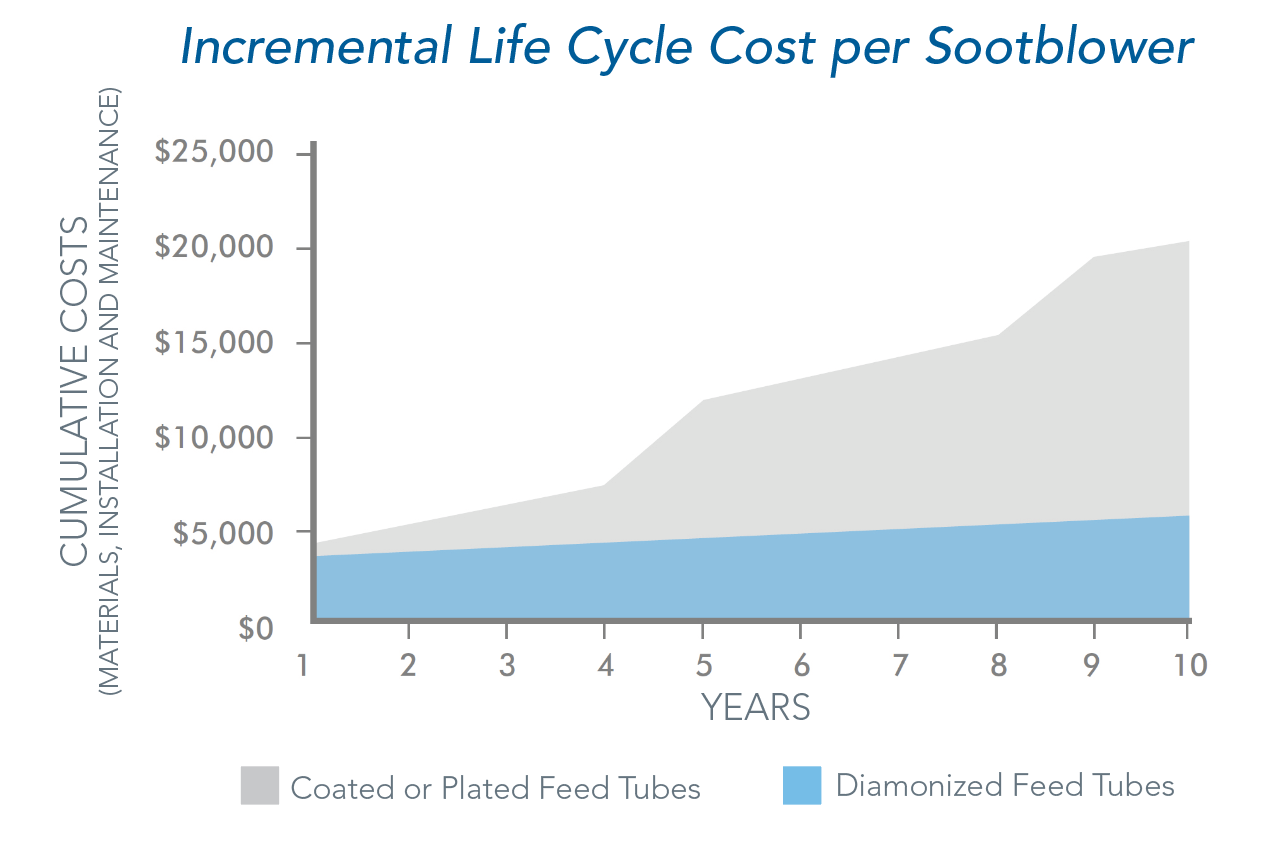

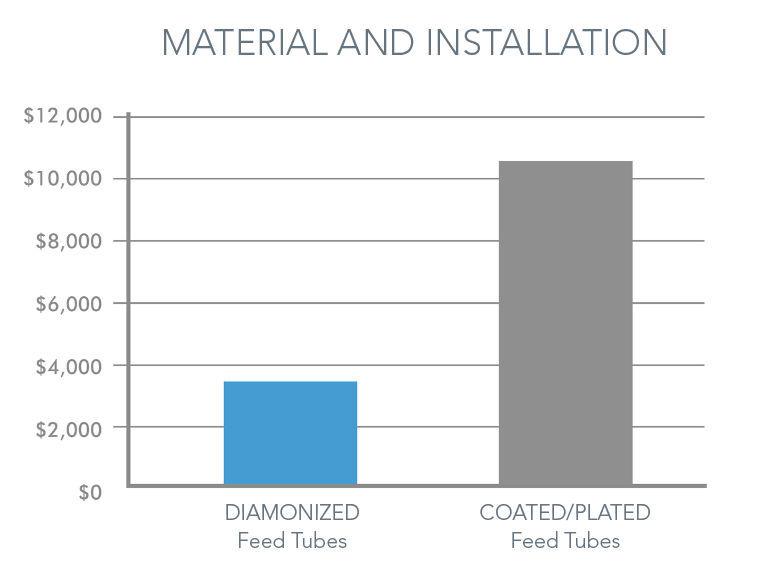

- Material and installation: The Diamonized feed tubes performed for 10 years, while traditional tubes are typically replaced every 3 years.

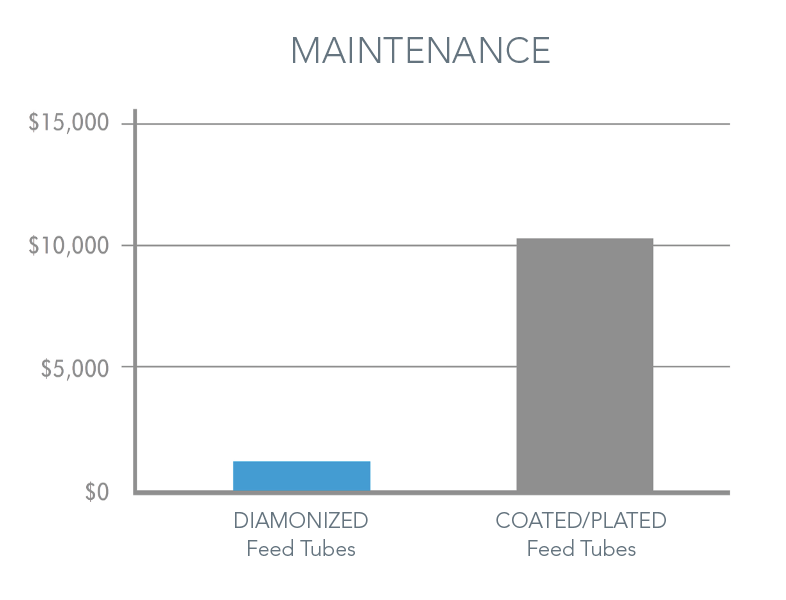

- Maintenance time and costs: The mill saved $8,160 in maintenance costs, in addition to $5,600 in material costs, for each sootblower.

- Steam savings: Typical feed tube packing leak accounts for approximately 300 lb/hour of steam mass flow. When annualized, this represents $12,600 per year, or more than $126,000 during the 10-year life of each Diamonized Feed Tube.